Cold Forming Trimming Dies and Cutting Dies

12.12.2024

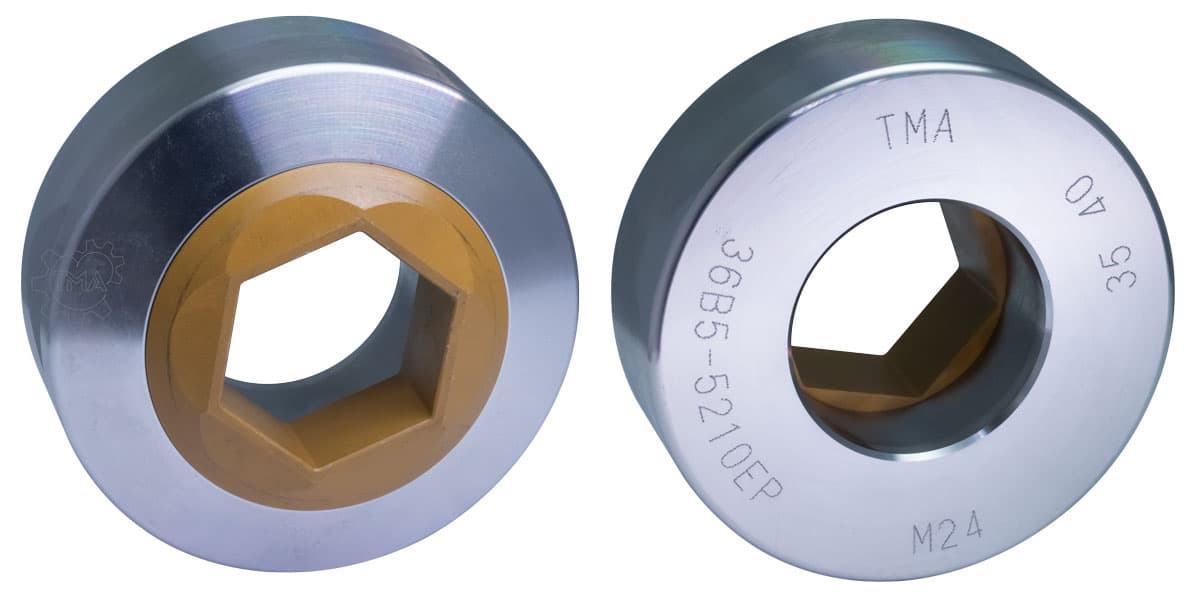

Cold Forming Trimming Dies and Cutting Dies: Essential Tools for Precision and Efficiency

In the world of cold forming, precision is paramount. The tooling used to shape, trim, and cut metal components plays a crucial role in ensuring the accuracy, functionality, and overall quality of the final product. Among the most important tools in cold forming operations are cold forming trimming dies or cutting dies. These dies are integral to the manufacturing of fasteners, automotive parts, and various other metal components that require precise cutting and trimming for optimal performance.

In this blog, we will explore the significance of cold forming trimming dies, their functions, and why investing in high-quality tools like those provided by Taiwan Metiz Alliance (TMA) is essential for achieving optimal results.

What are Cold Forming Trimming Dies?

Cold forming is a manufacturing process where metal is shaped at room temperature using high-pressure stamping or forging. Cold forming trimming dies are essential for removing excess material or flash from parts that are formed in a press or die. These dies are used at the end of the cold heading or cold forging process to "trim" the formed parts to their required shape, size, and finish.

Trimming dies are used for a variety of purposes, including:

- Flash Removal: Flash refers to excess material that flows beyond the die cavity during the forming process. Trimming dies help remove this excess material to ensure the part has clean, sharp edges and is within tolerance.

- Size Control: Trimming dies ensures that the parts are accurately sized, which is critical in applications where precise dimensions are necessary.

- Finishing: In some cases, trimming dies can also provide a smooth, burr-free surface finish on the part, improving both the aesthetic and functional qualities of the component.

Trimming dies (cutting dies) are commonly used in industries such as fastener manufacturing, automotive, aerospace, and electronics. These dies must be carefully engineered to accommodate the material properties of the parts being formed, as well as the type of forming process being used.

The Importance of Cutting Dies in Cold Forming

Cutting dies, on the other hand, are tools used to cut metal components to the desired shape or size during the cold forming process. These dies are typically used to cut blanks from larger metal sheets or bars and are designed to provide clean, accurate cuts with minimal deformation of the material.

Some of the key functions of cutting dies in cold forming include:

- Blanking: Cutting dies are often used to "blank" out metal shapes that will later be further processed or formed into final components. This is a critical step in manufacturing parts for industries such as automotive, aerospace, and electronics.

- Part Separation: In many cases, cutting dies are used to separate individual parts from a larger sheet or coil of metal. These dies help create the individual components required for final assembly.

- Shaping and Sizing: Cutting dies can also be designed to trim or shape parts to a precise size, ensuring that the components fit perfectly within the assembly.

High-quality cutting dies must be able to withstand the stresses of continuous use, as well as the forces applied during the cutting process. They must be made from durable materials, such as high-speed steel or tungsten carbide, to ensure a long lifespan and minimal wear.

Benefits of Investing in High-Quality Cold Forming Trimming or Cutting Dies

Investing in high-quality cold forming trimming or cutting dies offers several significant benefits for manufacturers. Some of the most notable advantages include:

- Increased Precision: High-quality cutting dies to ensure that parts are accurately sized and shaped, reducing the risk of defects and rework. This precision is especially important in industries where tight tolerances are required, such as in the production of fasteners and automotive components.

- Improved Efficiency: Well-designed dies help streamline the manufacturing process by reducing downtime, improving cycle times, and minimizing material waste. This can lead to greater productivity and cost savings.

- Extended Tool Life: Investing in durable, high-performance dies means that they will last longer, reducing the need for frequent replacements and minimizing production interruptions. Dies made from high-quality materials, such as tungsten carbide, offer superior wear resistance and maintain their sharpness for longer periods.

- Reduced Maintenance Costs: With superior design and materials, high-quality trimming or cutting dies require less maintenance and can handle more cycles before requiring servicing or replacement. This results in cost savings over time.

- Consistent Quality: Quality tooling ensures that the final products are of consistent quality, which is crucial for industries where part reliability and safety are essential, such as in automotive and aerospace applications.

Why Taiwan Metiz Alliance?

Taiwan Metiz Alliance (TMA) has established itself as a trusted manufacturer of cold forming trimming dies. The company has been in business for over 25 years and is known for its commitment to quality, precision, and innovation. TMA's dies are crafted using premium materials such as Japanese and European tungsten carbide and steel, ensuring optimal durability and performance. Each die undergoes rigorous testing and inspection to guarantee it meets the highest standards of quality and functionality.

TMA offers a wide range of dies, including custom designs tailored to meet specific customer requirements. Their dies are compatible with various cold forming machines and are designed to handle even the most challenging materials and applications.

Cold Forming trimming dies are essential tools for achieving high-quality, precise components in a variety of industries. By investing in high-quality tooling, manufacturers can improve the efficiency, precision, and longevity of their production processes, ultimately leading to greater customer satisfaction and cost savings. Taiwan Metiz Alliance offers the expertise, experience, and cutting-edge technology needed to provide reliable, high-performance dies that meet the demands of modern manufacturing.

If you're looking for high-quality cutting dies, Taiwan Metiz Alliance is here to provide the tools you need to succeed. Contact us today to learn more about our products and how we can help optimize your production process.