FLUTELESS MACHINE TAPS FOR THREAD ROLLING MACHINES

FLUTELESS MACHINE TAPS FOR STEEL

Applications of Fluteless Machine Taps

Fluteless Machine Taps (chipless taps, cold forming taps) are recommended to be used when producing threads by plastic deformation (rolling) in parts made of non-ferrous and ferrous metals with high plasticity. These materials include: aluminum and its alloys, copper, brass, bronze with a high copper content, zinc and its alloys, low-carbon and high-plastic stainless and heat-resistant steels. Compared to cutting taps, forming taps have greater strength, provide accurate threads with low surface roughness, and increase thread strength (up to 20%).

Their main difference from cutting taps is the absence of longitudinal grooves that form cutting edges. In addition, the champfer on these taps is significantly shorter. At the end of the threaded part of the fluteless taps, there are small symmetrically located coolant grooves.

Fluteless taps are much stronger than cutting taps, their breakages are very rare and there are almost no defects of parts due to taps breakdowns. Thanks to the long threaded part, the tap can be re-sharpened several times. Thus, the service life of the fluteless tap is much longer than regular tap.

High productivity in threading is the main advantage of fluteless machine taps. They are used for thread forming not only in through holes, but also in blind holes. The thread rolling profile is formed by pressing the tool into the workpiece material and extruding part of the material into the tool cavity.

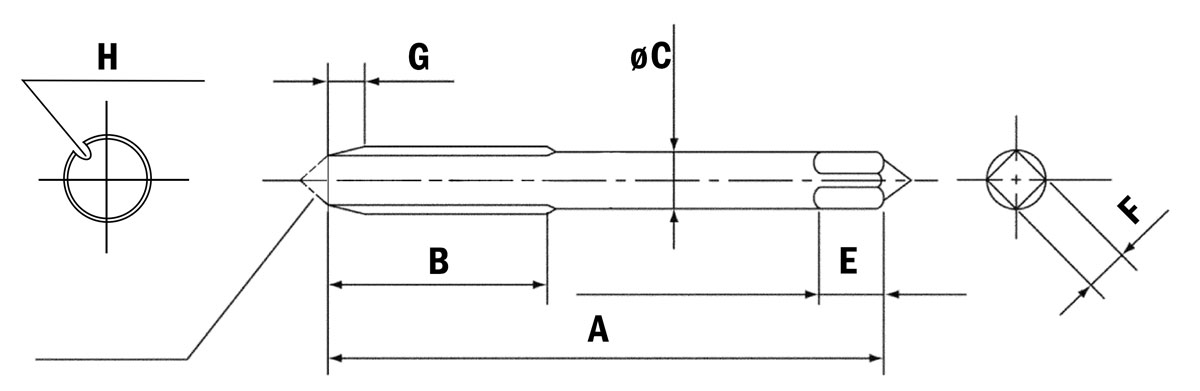

Outlook & Drawing of Fluteless Machine Taps for Steel

G - Chamfer Length: 2 threads for blind holes (B) or 4 threads for through holes (P)

H - lubricating groove

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | E square length | F square | number of facets | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| size | tolerance | size | tolerance | size | tolerance | size | tolerance | |||

| M 2 | 40 | ±0.7 | 12 | ±1 | 3 | 0 -0.04 | 5 | 2.5 | 0 -0.1 | 4 |

| 2.5 | 44 | 〞 | 14 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 2.6 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| M 3 | 46 | 〞 | 9 | 〞 | 4 | 〞 | 6 | 3.2 | 〞 | 4 |

| 3.5 | 48 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 4 | 52 | 〞 | 10 | 〞 | 5 | 〞 | 7 | 4 | 〞 | 〞 |

| 4.5 | 55 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 5 | 60 | 〞 | 11 | 〞 | 5.5 | 〞 | 〞 | 4.5 | 〞 | 〞 |

| 5.5 | 60 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 6 | 62 | 〞 | 12 | 〞 | 6 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 7 | 65 | 〞 | 16 | 〞 | 6.2 | 〞 | 8 | 5 | 〞 | 6 |

| 8 | 70 | ±1.2 | 18 | ±1.4 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 9 | 72 | 〞 | 〞 | 〞 | 7 | 〞 | 〞 | 5.5 | 〞 | 〞 |

| 10 | 75 | 〞 | 19 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 8 |

| 11 | 80 | 〞 | 23 | 〞 | 8 | 〞 | 9 | 6 | 〞 | 〞 |

| 12 | 82 | 〞 | 〞 | 〞 | 8.5 | 〞 | 〞 | 6.5 | 〞 | 〞 |

| 14 | 88 | 〞 | 25 | 〞 | 10.5 | 〞 | 11 | 8 | 〞 | 〞 |

| 15 | 90 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 16 | 95 | 〞 | 27 | 〞 | 12.5 | 0 -0.05 | 13 | 10 | 0 -0.15 | 〞 |

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | E square length | F square | number of facets | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| size | tolerance | size | tolerance | size | tolerance | size | tolerance | |||

| No .2 | 42 | ±0.7 | 13 | ±1 | 3 | 0 -0.04 | 5 | 2.5 | 0 -0.1 | 4 |

| No .3 | 44 | 〞 | 14 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| No .4 | 〞 | 〞 | 15 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| No .5 | 46 | 〞 | 9 | 〞 | 4 | 〞 | 6 | 3.2 | 〞 | 〞 |

| 6 | 48 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 8 | 52 | 〞 | 10 | 〞 | 5 | 〞 | 7 | 4 | 〞 | 〞 |

| 10 | 60 | 〞 | 11 | 〞 | 5.5 | 〞 | 〞 | 4.5 | 〞 | 〞 |

| 12 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 | 〞 |

| U 1 / 4 | 62 | 〞 | 14 | ±14 | 6 | 〞 | 〞 | 〞 | 〞 | 〞 |

| 5 / 16 | 70 | ±1.2 | 18 | 〞 | 6.1 | 〞 | 8 | 5 | 〞 | 6 |

| 3 / 8 | 75 | 〞 | 21 | 〞 | 7 | 〞 | 〞 | 5.5 | 〞 | 8 |

| 7 / 16 | 80 | 〞 | 23 | 〞 | 8 | 〞 | 9 | 6 | 〞 | 〞 |

| 1 / 2 | 85 | 〞 | 25 | 〞 | 9 | 〞 | 10 | 7 | 〞 | 〞 |

| 9 / 16 | 90 | 〞 | 〞 | 〞 | 10.5 | 〞 | 11 | 8 | 〞 | 〞 |

| 5 / 8 | 95 | 〞 | 27 | 〞 | 12 | 0 -0.05 | 12 | 9 | 〞 | 〞 |

Ordering of Fluteless Machine Taps for Steel

| RG NO. | Thread Size | TAP Limit | Chamfer (G) | Total Length (A) | Thread Length (B) | Shank Dia. (C) |

|---|---|---|---|---|---|---|

| 1000021134 | M2 X 0.4 | RH5 | P | 40 | 12 | 3 |

| 1000021135 | M2 X 0.4 | RH5 | B | 40 | 12 | 3 |

| 1000021182 | M2.6 X 0.45 | RH5 | P | 44 | 14 | 3 |

| 1000021183 | M2.6 X 0.45 | RH5 | B | 44 | 14 | 3 |

| 1000125816 | M3 X 0.5 | RH6 | P | 46 | 9 | 4 |

| 1000125817 | M3 X 0.5 | RH6 | B | 46 | 9 | 4 |

| 1000125820 | M4 X 0.7 | RH7 | P | 52 | 10 | 5 |

| 1000125821 | M4 X 0.7 | RH7 | B | 52 | 10 | 5 |

| 1000125828 | M5 X 0.8 | RH7 | P | 60 | 11 | 5.5 |

| 1000125829 | M5 X 0.8 | RH7 | B | 60 | 11 | 5.5 |

| 1000125836 | M6 X 1 | RH8 | P | 62 | 12 | 6 |

| 1000125837 | M6 X 1 | RH8 | B | 62 | 12 | 6 |

| 1000012476 | M8 X 1.25 | RH7 | P | 70 | 18 | 6.2 |

| 1000012477 | M8 X 1.25 | RH7 | B | 70 | 18 | 6.2 |

| 1000012478 | M8 X 1.25 | RH8 | P | 70 | 18 | 6.2 |

| 1000012479 | M8 X 1.25 | RH8 | B | 70 | 18 | 6.2 |

| 1000125842 | M8 X 1 | RH8 | P | 70 | 18 | 6.2 |

| 1000125843 | M8 X 1 | RH8 | B | 70 | 18 | 6.2 |

| 1000012508 | M10 X 1.5 | RH7 | P | 75 | 19 | 7 |

| 1000012509 | M10 X 1.5 | RH7 | B | 75 | 19 | 7 |

| 1000125854 | M10 X 1.5 | RH8 | P | 75 | 19 | 7 |

| 1000125855 | M10 X 1.5 | RH8 | B | 75 | 19 | 7 |

| 1000012522 | M10 X 1.25 | RH7 | P | 75 | 19 | 7 |

| 1000012523 | M10 X 1.25 | RH7 | B | 75 | 19 | 7 |

| 1000012524 | M10 X 1.25 | RH8 | P | 75 | 19 | 7 |

| 1000012525 | M10 X 1.25 | RH8 | B | 75 | 19 | 7 |

| 1000128843 | M12 X 1.75 | RH9 | P | 82 | 23 | 8.5 |

| 1000128844 | M12 X 1.75 | RH9 | B | 82 | 23 | 8.5 |

| 1000128841 | M12 X 1.5 | RH8 | P | 82 | 23 | 8.5 |

| 1000128842 | M12 X 1.5 | RH8 | B | 82 | 23 | 8.5 |

| 1000012576 | M12 X 1.25 | RH7 | P | 82 | 23 | 8.5 |

| 1000012577 | M12 X 1.25 | RH7 | B | 82 | 23 | 8.5 |

| 1000012594 | M12 X 1 | RH7 | P | 82 | 23 | 8.5 |

| 1000012595 | M12 X 1 | RH7 | B | 82 | 23 | 8.5 |

| 1000012612 | M14 X 2 | RH10 | P | 88 | 25 | 10.5 |

| 1000012613 | M14 X 2 | RH10 | B | 88 | 25 | 10.5 |

| 1000012626 | M14 X 1.5 | RH9 | P | 88 | 25 | 10.5 |

| 1000012627 | M14 X 1.5 | RH9 | B | 88 | 25 | 10.5 |

| 1000012640 | M16 X 2 | RH10 | P | 95 | 27 | 12.5 |

| 1000012641 | M16 X 2 | RH10 | B | 95 | 27 | 12.5 |

| 1000012654 | M16 X 1.5 | RH9 | P | 95 | 27 | 12.5 |

| 1000012655 | M16 X 1.5 | RH9 | B | 95 | 27 | 12.5 |

| 1000012668 | M18 X 2.5 | RH11 | P | 100 | 29 | 14 |

| 1000012669 | M18 X 2.5 | RH11 | B | 100 | 29 | 14 |

| 1000012684 | M18 X 1.5 | RH10 | P | 100 | 29 | 14 |

| 1000012685 | M18 X 1.5 | RH10 | B | 100 | 29 | 14 |

| 1000012686 | M20 X 2.5 | RH11 | P | 105 | 30 | 15 |

| 1000012687 | M20 X 2.5 | RH11 | B | 105 | 30 | 15 |

| 1000012688 | M20 X 1.5 | RH10 | P | 105 | 30 | 15 |

| 1000012689 | M20 X 1.5 | RH10 | B | 105 | 30 | 15 |

| RG NO. | Thread Size | TAP Limit | Chamfer (G) | Total Length (A) | Thread Length (B) | Shank Dia. (C) |

|---|---|---|---|---|---|---|

| 1000125910 | NO.4 - 40 UNC | RH6 | P | 44 | 15 | 3 |

| 1000125911 | NO.4 - 40 UNC | RH6 | B | 44 | 15 | 3 |

| 1008307092 | NO.6 - 32 UNC | RH7 | P | 48 | 9 | 4 |

| 1008307093 | NO.6 - 32 UNC | RH7 | B | 48 | 9 | 4 |

| 1008307108 | NO.8 - 32 UNC | RH7 | P | 52 | 10 | 5 |

| 1008307109 | NO.8 - 32 UNC | RH7 | B | 52 | 10 | 5 |

| 1008307124 | NO.10 - 24 UNC | RH8 | P | 60 | 11 | 5.5 |

| 1008307125 | NO.10 - 24 UNC | RH8 | B | 60 | 11 | 5.5 |

| 1000125928 | NO.10 - 32 UNF | RH8 | P | 60 | 11 | 5.5 |

| 1000125929 | NO.10 - 32 UNF | RH8 | B | 60 | 11 | 5.5 |

| 1008307140 | NO.12 - 24 UNC | RH8 | P | 60 | 11 | 5.5 |

| 1008307141 | NO.12 - 24 UNC | RH8 | B | 60 | 11 | 5.5 |

| 1008307156 | 1/4 - 20 UNC | RH8 | P | 62 | 14 | 6 |

| 1008307157 | 1/4 - 20 UNC | RH8 | B | 62 | 14 | 6 |

| 1000125938 | 1/4 - 28 UNF | RH8 | P | 62 | 14 | 6 |

| 1000125939 | 1/4 - 28 UNF | RH8 | B | 62 | 14 | 6 |

| 1000125944 | 5/16 - 24 UNF | RH8 | P | 70 | 18 | 6.1 |

| 1000125945 | 5/16 - 24 UNF | RH8 | B | 70 | 18 | 6.1 |

| 1000129160 | 5/16 - 18 UNC | RH8 | P | 70 | 18 | 6.1 |

| 1000129161 | 5/16 - 18 UNC | RH8 | B | 70 | 18 | 6.1 |

| 1000129164 | 3/8 - 16 UNC | RH8 | P | 75 | 21 | 7 |

| 1000129165 | 3/8 - 16 UNC | RH8 | B | 75 | 21 | 7 |

| 1000125948 | 3/8 - 16 UNC | RH9 | P | 75 | 21 | 7 |

| 1000125949 | 3/8 - 16 UNC | RH9 | B | 75 | 21 | 7 |

| 1000125950 | 3/8 - 24 UNF | RH8 | P | 75 | 21 | 7 |

| 1000125951 | 3/8 - 24 UNF | RH8 | B | 75 | 21 | 7 |

| RG NO. | Thread Size | TAP Limit | Chamfer (G) | Total Length (L) | Thread Length (B) | Shank Dia. (C) |

|---|---|---|---|---|---|---|

| 125970 | W1/8 - 40 | RH6 | P | 46 | 9 | 4 |

| 125971 | W1/8 - 40 | RH6 | B | 46 | 9 | 4 |

| 125972 | W5/32 - 32 | RH7 | P | 52 | 10 | 5 |

| 125973 | W5/32 - 32 | RH7 | B | 52 | 10 | 5 |

| 125974 | W3/16 - 24 | RH7 | P | 60 | 11 | 5.5 |

| 125975 | W3/16 - 24 | RH7 | B | 60 | 11 | 5.5 |

| 125976 | W1/4 - 20 | RH8 | P | 62 | 14 | 6 |

| 125977 | W1/4 - 20 | RH8 | B | 62 | 14 | 6 |

| 129850 | W1/4 - 20 | RH7 | P | 62 | 14 | 6 |

| 129851 | W1/4 - 20 | RH7 | B | 62 | 14 | 6 |

| 129852 | W5/16 - 18 | RH8 | P | 70 | 18 | 6.1 |

| 129853 | W5/16 - 18 | RH8 | B | 70 | 18 | 6.1 |

| 129854 | W3/8 - 16 | RH8 | P | 75 | 21 | 7 |

| 129855 | W3/8 - 16 | RH8 | B | 75 | 21 | 7 |