TOOLING FOR THREAD-ROLLING MACHINES

TMA PLANE THREAD-ROLLING DIES FOR TAPPING SCREWS, BOLTS, SELF-TAPPING SCREWS

Plane thread-rolling dies are used for manufacture of metric threads in structural steel products.

Thread rolling dies production in Taiwan was founded in 1981. Currently, Taiwan is number one in manufacturing of dies for thread-rolling on screw products. In 31 years dies production technology have been developed and improved, the license to manufacture TMA products was obtained.

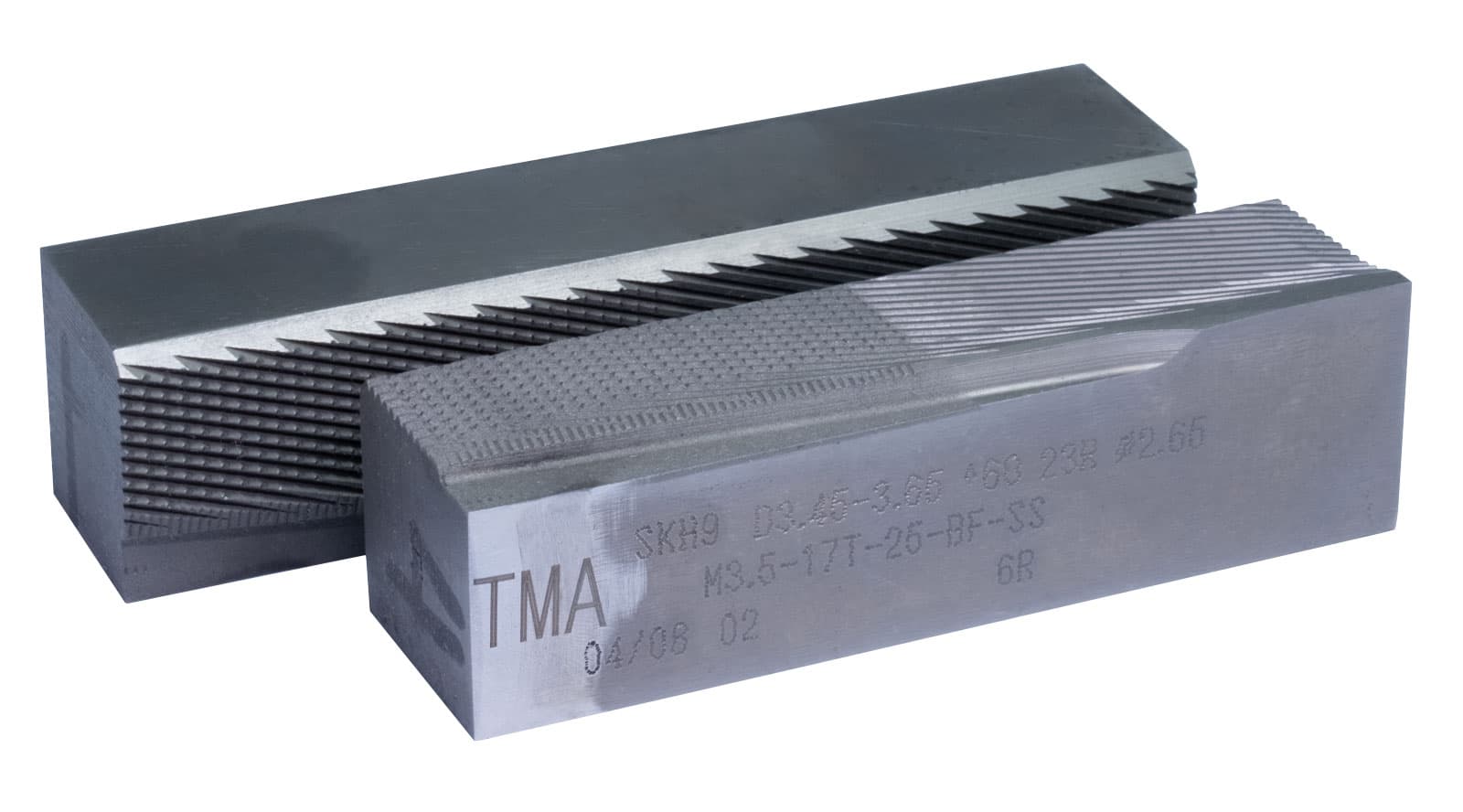

Currently our company continues to invest in development, technological infrastructure, investigation of metal properties and strict quality control at all stages of dies production. Service and permanent control of product quality determines the manufacturer's brand. In thread rolling dies production used exclusively blank material made in Japan.

Features of TMA Flat Thread Rolling Dies

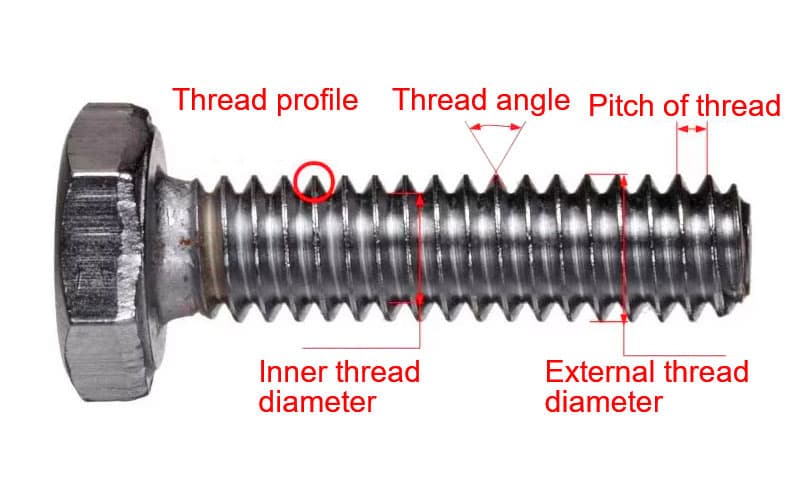

High performance flat thread rolling dies for metric and inch types of threads for bolts, self-tapping screws, screws and screws have the following features:

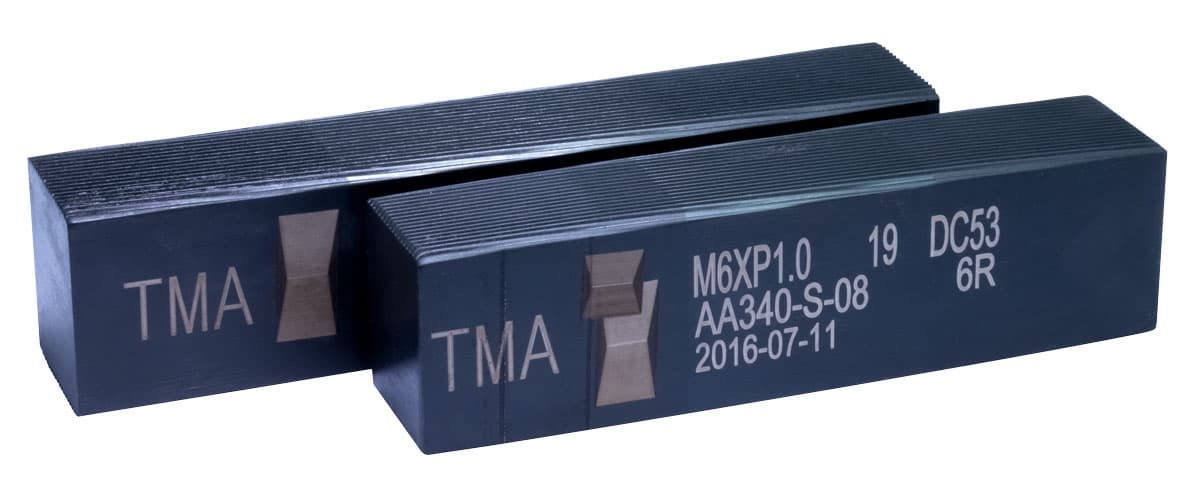

- Thread rolling flat dies for rolling metric and inch threads of bolts, self-tapping screws and screws are made of alloy tool steel with high hardness and strength on precision CNC machines.

- The production of dies is fully automated, thread-rolling dies are made under full automatic computerized machinery precision processing procedure.

- Self-tapping thread rolling dies are produced with excellent heat treatment and are truly durable. The hardness of the die after heat treatment is 64-65HRC. Under normal operating conditions, the average service life of one set of self-tapping dies exceeds 3 million pieces.

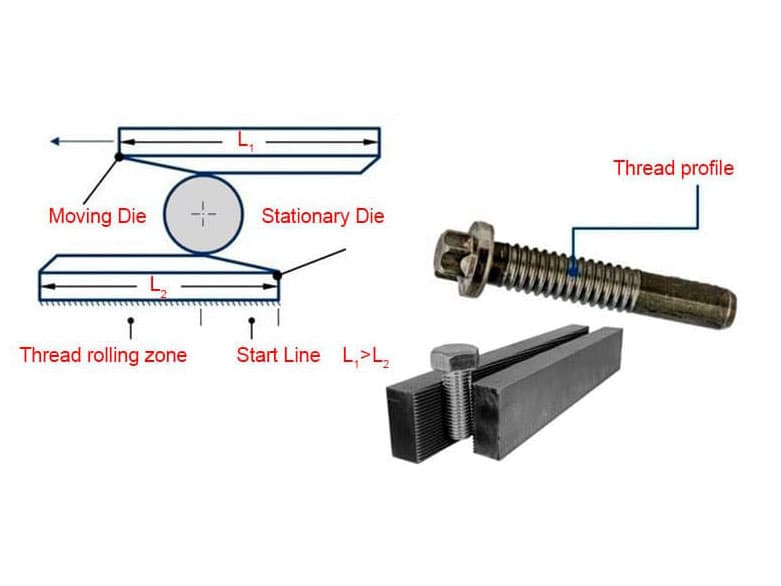

- Computer programs are applied to ensure the accuracy of all dimensions. On the top of the movable die, a starting line is applied, which can be used to set its position relative to the fixed die before material feeding, for faster thread pitch adjustment.

- Plane thread-rolling dies for the formation of a gimbal are applicable for high-speed production of single-start and double-start threads for self-tapping screws, wood screws, self-tapping screws for drywall and with a drill tip, as well as self-tapping screws for sandwich panels and various specialized types and forms of threads.

- The thread rolling tool can be made of high speed steel (HSS), high alloy tool steel (D). New types of HIH and HID dies have undergone a special anti-slip treatment. HIH series dies are suitable for high strength and stainless steel self-tapping screws used in the automotive and aerospace industries. HIDs are suitable for the production of stainless steel screws that have a service life of 200% longer than conventional self-tapping screws.

- Size range of dies for rolling metric and inch threads: Length 950 mm × Height 400 mm × Thickness 120 mm, minimum thread pitch 0.25 mm.

- Available in Standard, as well as Non-Standard, sizes as per requirement.

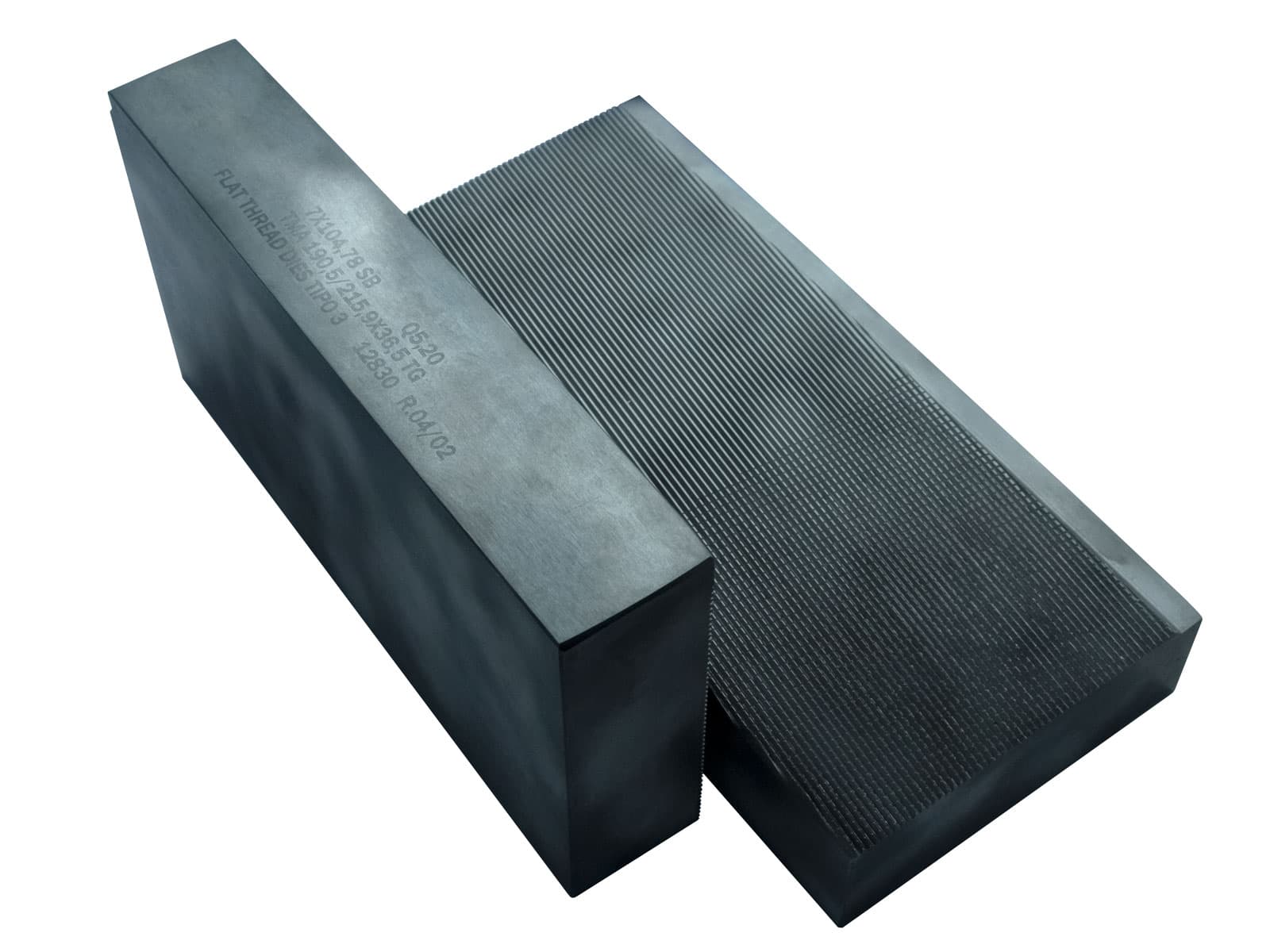

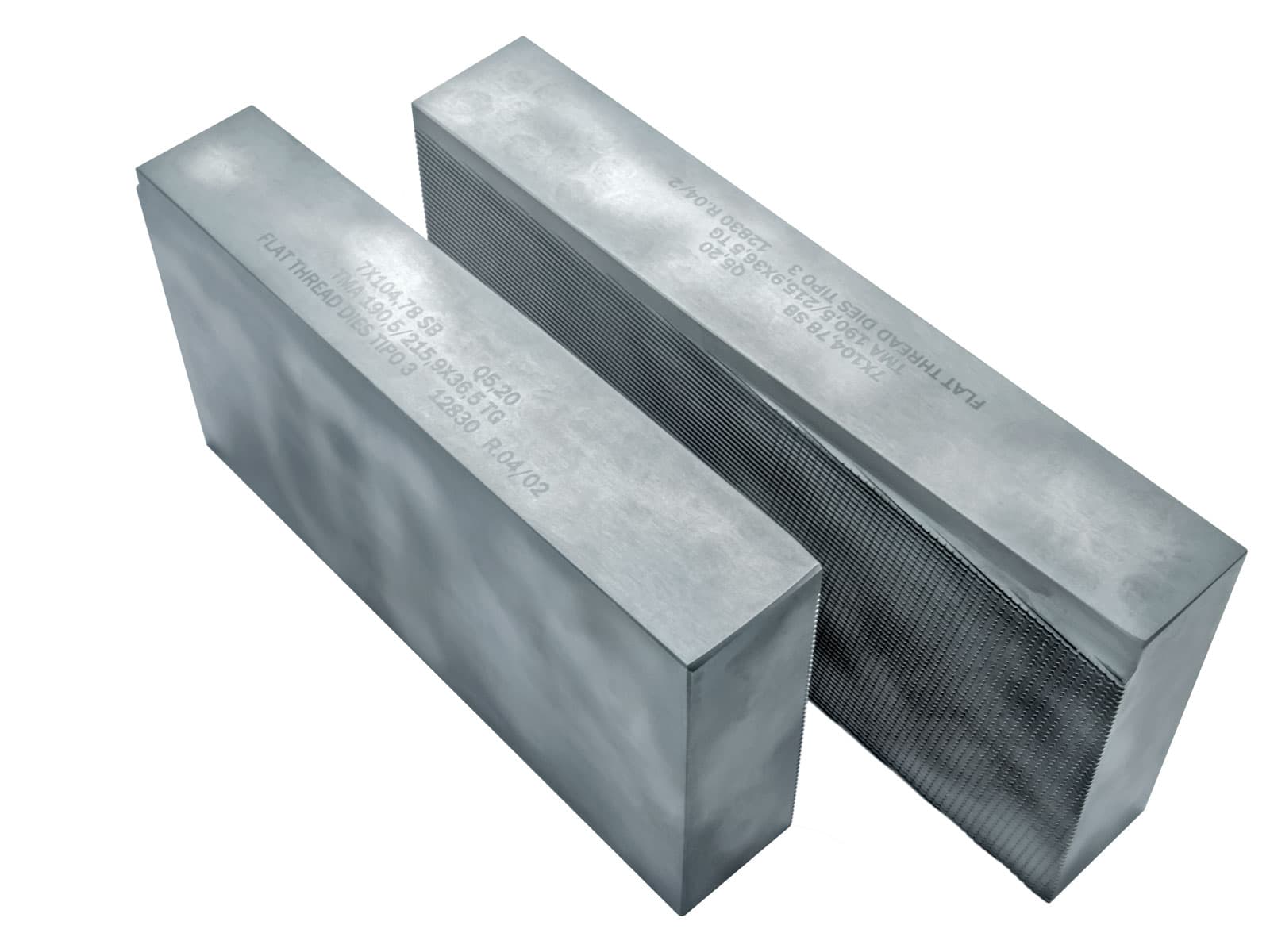

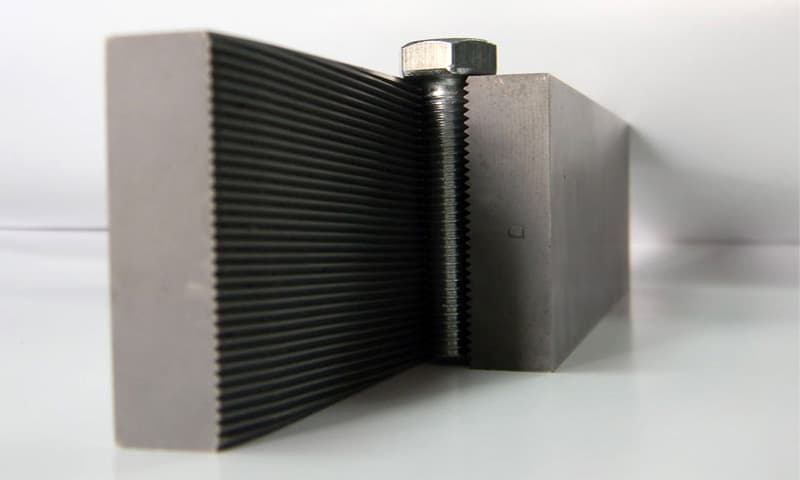

Thread rolling with Thread rolling flat Die

Flat dies system has two die flats, the bottom one is held stationary and the other slides. The blank is placed of one end of the stationary died then the moving die slides over the blank, which causes the blank to roll off the stationary lower die in a finished form. Flat dies are available in various thread forms such as ANSI, BS, DIN and JIS amongst other. It can be offered with or without holding angles. Flat dies produce external threads by the process of cold forming, sutilize one stationary and one moving die to form the threads.

Special Thread Design

Our special thread design forces the two thread helixes to align, every time, without fail. The fasteners then drive easily, with reduced effort. It works with all types of nuts and internal threads, including lock nuts, making it very useful. It has unrivaled anti-cross thread performance whereby it never cross threads. This is backed with a hundred percent success record. It makes paint cutters obsolete due to the fact that it is unaffected by paint in internal threads or excess paint. This new technology has changed the course of car assembly. Installers exclaim that it “glides in” and they are ecstatic over its ease and efficiency.

It aligns components by itself, even the must stubborn situations. This is done by finding holes and forcing itself straight up. It also fixes clogged internal threads because it slides through paint build ups. It is user friendly and versatile, and more importantly, it never fails to work. Its superior performance level makes it attractive and trustworthy to all investors and it lives up to their expectation. The special thread designs have delivered a track record like no other fastener. Their ease of use has enabled labor reductions and its efficiency has reduced costs, replacements, and maintenance.

Benefits: eliminates cross threading, repairs paint-clogged internal threads, eases instillation of all parts, eliminates hand strarting, helps align parts

THREAD-ROLLING DIES DIMENSIONS

| General model | Machine type | S (die width) | H (die height) | L1 (fixed length) | L2 (adjustable length) |

|---|---|---|---|---|---|

| Machine No. 0 | 19 | 25 | 51 | 64 | |

| Machine No. 3/16 | 25 | 25.40.45.53 | 75 | 90 | |

| Machine No. 1/4 | 25 | 25.40.55.65.80.105 | 100 | 115 | |

| Machine No. 5/16 | 25 | 25.40.55.65.80.105 | 127 | 140 | |

| Machine No. 3/8 | 25 | 25.40.55.65.80.105 | 150 | 165 | |

| Machine No. 1/2 | 35 | 55.80.105.125.150 | 190 | 215 | |

| Machine No. 3/4 | 38 | 55.80.105.125.150 | 230 | 265 | |

| Special model | Machine No. 003 | 15 | 20 | 45 | 55 |

| Machine No. 004 | 20 | 25 | 65 | 80 | |

| Machine No. 4R | 20 | 25.30.35.40 | 65 | 75 | |

| Machine No. 6R | 25 | 25.30.40.55.65 | 90 | 105 | |

| Machine No. 8R | 25 | 25.30.40.55.65.80.105 | 108 | 127 | |

| Machine No. 250 | 25 | 25.40.55 | 110 | 125 | |

| Machine No. DR125 | 20.8 | 25.40.55 | 73.3 | 86.2 | |

| Machine No. DR200 | 20.8 | 25.40.53.65.80 | 92.3 | 105.2 gradient 5º | |

| Machine No. DR250 | 23.8 | 25.40.54.65.80.105 | 112.1 | 131.2 gradient 5º |

Tools and accessories according to the finished product drawings

We are able to design tools and accessories according to the finished product drawings and technical requirements. It is necessary to specify the model of the machine, the material of the dies, the dimensions of the dies, the diameter of the wire, the dimensions of the product, the accuracy and pitch of the thread, the metric and inch specification of the thread, the shape of the outer surface of the dies (round, square, hexagonal, prismatic), the dimensions S, H, L1, L2 and the number of sets to be purchased.

THREAD-ROLLING DIES SPECIFICATIONS

| Machine model | Movable die | Fixed die | Die height | Die width |

|---|---|---|---|---|

| 201 | 55 | 45 | 25 | 20 |

| 202 | 65 | 55 | 30 | 24 |

| 203 | 80 | 70 | 30 | 24 |

| 204 | 100 | 85 | 40 | 24 |

| 205 | 115 | 100 | 55 | 24 |

| 302 | 125 | 110 | 40 | 24 |

| 206 | 145 | 125 | 55 | 30 |

| 207 | 170 | 150 | 55 | 30 |

| 208 | 210 | 190 | 55 | 40 |

| 209 | 250 | 230 | 65 | 45 |

| 210 | 250 | 230 | 80 | 50 |

| 234 | 145 | 125 | 80 | 40 |

| 235 | 170 | 150 | 80 | 40 |

| 237 | 210 | 190 | 80 | 40 |

| 238 | 210 | 190 | 105 | 40 |

| 236 | 170 | 150 | 105 | 40 |

| 213 | 310 | 285 | 80 | 50 |

| 214 | 310 | 285 | 105 | 50 |

Main threads rolled up by flat threaded dies

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)