TOOLS FOR THREAD ROLLING MACHINES

Nut taps for carbon steel nuts and cold formed nuts

Purpose and features of nut taps

Nut taps are used to cut through threads in nuts in one pass without screwing the nuts by threading them onto the shank end. Nut Tap for Carbon Steel is standard items, that can either be used by connecting to a bent shank or short shank. Used on special Automatic Nuts Tapping Machine.

- These nut taps are used for threading carbon steel nuts on automatic thread rolling machines.

- Special chip flute design provides better chip evacuation when threading carbon steel nuts.

- These nut taps are available in metric, american and imperial threads.

- Total length from 55 to 165 mm with thread length from 12 to 95 mm.

- The standard thread length is 25 and 30 threads.

- Round shank.

- We make design and manufacture of nut taps according to customer requirements.

- Tool Material Type: Vanadium-containing High-Speed Steel (HSSE)

- Surface treatment of nut taps: Titanium Nitride (TiN)

- The nut taps are manufactured with GH accuracy class (13 µm).

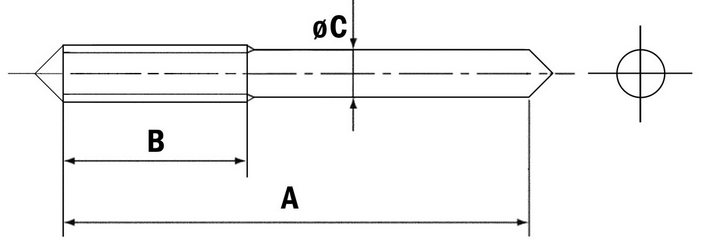

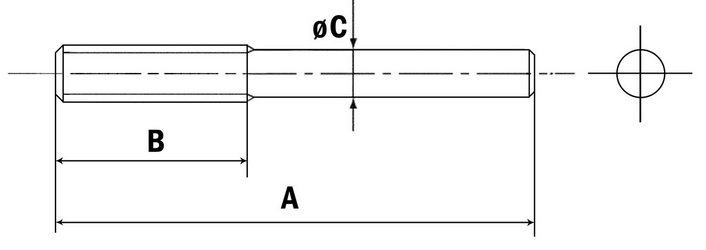

Outlook & Drawing of Nut taps for carbon steel cold formed nuts

nut taps for threads M7 (U1/4) and smaller

nut taps for threads M8 (U5/16) and larger

Table 1. Metric Coarse Threads (M)

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | Number of grooves | |

|---|---|---|---|---|---|

| 25 treads | 30 treads (SUS) | ||||

| M3 × 0.5 | 58.7 | 12.5 | 15 | 2.3 | 3 |

| M3.5 × 0.6 | 58.5 | 15 | 18 | 2.3 | 3 |

| M4 × 0.7 | 58.3 | 17.5 | 21 | 3 | 3 |

| M4.5 × 0.75 | 58 | 18.8 | 22.5 | 3.5 | 3 |

| M5 × 0.8 | 62.8 | 20 | 24 | 3.8 | 3 |

| M6 × 1 | 67.4 | 25 | 30 | 4.6 | 3 |

| M7 × 1 | 70 | 25 | 30 | 5.6 | 3 |

| M8 × 1.25 | 77 | 31.3 | 37.5 | 6 | 5 |

| M9 ×1.25 | 89 | 31.3 | 37.5 | 7 | 5 |

| M10 × 1.5 | 89 | 37.5 | 45 | 8 | 5 |

| M11 × 1.5 | 102 | 37.5 | 45 | 8.8 | 5 |

| M12 × 1.75 | 102 | 43.8 | 52.5 | 9.5 | 5 |

| M14 × 2 | 114 | 50 | 60 | 11.2 | 5 |

| M16 × 2 | 127 | 50 | 60 | 13.1 | 5 |

| M18 × 2.5 | 133 | 62.5 | 75 | 14 | 5 |

| M20 × 2.5 | 133 | 62.5 | 75 | 16.5 | 5 |

| M22 × 2.5 | 146 | 62.5 | 75 | 17.5 | 5 |

| M24 × 3 | 165 | 75 | 90 | 18.5 | 5 |

| M27 × 3 | 165 | 75 | 90 | 21.5 | 5 |

Table 2. Metric fine threads (MF)

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | Number of grooves | |

|---|---|---|---|---|---|

| 25 treads | 30 treads (SUS) | ||||

| M4 × 0.5 | 58.1 | 12.5 | 15 | 3 | 3 |

| M5 × 0.5 | 62.6 | 12.5 | 15 | 4 | 3 |

| M6 × 0.75 | 67.2 | 18.8 | 22.5 | 4.5 | 3 |

| M7 × 0.75 | 70 | 18.8 | 22.5 | 5.5 | 3 |

| M8 × 0.75 | 76 | 18.8 | 22.5 | 6.5 | 5 |

| M9 × 0.75 | 89 | 18.8 | 22.5 | 7.5 | 5 |

| M8 × 1 | 77 | 25 | 30 | 6.6 | 5 |

| M9 × 1 | 89 | 25 | 30 | 7.6 | 5 |

| M10 × 1 | 89 | 25 | 30 | 8.6 | 5 |

| M10 × 1.25 | 89 | 31.3 | 37.5 | 8 | 5 |

| M12 × 1.25 | 102 | 31.3 | 37.5 | 10 | 5 |

| M14 × 1.25 | 114 | 31.3 | 37.5 | 12 | 5 |

| M12 × 1.5 | 102 | 37.5 | 45 | 9.5 | 5 |

| M14 × 1.5 | 114 | 37.5 | 45 | 11.2 | 5 |

| M16 × 1.5 | 127 | 37.5 | 45 | 13.1 | 5 |

| M18 × 1.5 | 133 | 37.5 | 45 | 15 | 5 |

| M20 × 1.5 | 133 | 37.5 | 45 | 16.5 | 5 |

| M22 × 1.5 | 146 | 37.5 | 45 | 19 | 5 |

| M24 × 1.5 | 165 | 37.5 | 45 | 21.5 | 5 |

| M18 × 2 | 133 | 50 | 60 | 15 | 5 |

| M20 × 2 | 133 | 50 | 60 | 16.5 | 5 |

| M22 × 2 | 146 | 50 | 60 | 19 | 5 |

| M24 × 2 | 165 | 50 | 60 | 20 | 5 |

Table 3. American Coarse Treads (UNC)

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | Number of grooves | |

|---|---|---|---|---|---|

| 25 treads | 30 treads (SUS) | ||||

| No. 4-40UNC | 58.8 | 15.9 | 19.1 | 2 | 3 |

| No. 5-40UNC | 58.7 | 15.9 | 19.1 | 2.2 | 3 |

| No. 6-32UNC | 58.6 | 19.8 | 23.8 | 2.4 | 3 |

| No. 8-32UNC | 58.2 | 19.8 | 23.8 | 3.1 | 3 |

| No.10-24UNC | 63 | 26.5 | 31.8 | 3.4 | 3 |

| No.12-24UNC | 67.6 | 26.5 | 31.8 | 4 | 3 |

| 1/4-20UNC | 72.4 | 31.8 | 38.1 | 4.6 | 3 |

| 5/16-18UNC | 77 | 35.3 | 42.3 | 6 | 5 |

| 3/8-16UNC | 89 | 39.7 | 47.6 | 7.3 | 5 |

| 7/16-14UNC | 102 | 45.4 | 54.4 | 8.6 | 5 |

| 1/2-13UNC | 102 | 48.8 | 58.6 | 10 | 5 |

| 9/16-12UNC | 114 | 52.9 | 63.5 | 11 | 5 |

| 5/8-11UNC | 127 | 57.7 | 69.3 | 12.8 | 5 |

| 3/4-10UNC | 133 | 63.5 | 76.2 | 15 | 5 |

| 7/8-9UNC | 133 | 70.6 | 84.7 | 17 | 5 |

| 1"-8UNC | 165 | 79.4 | 95.3 | 20 | 5 |

Table 4. American Fine Treads (UNF)

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | Number of grooves | |

|---|---|---|---|---|---|

| 25 treads | 30 treads (SUS) | ||||

| No. 4-48UNF | 58.8 | 13.2 | 15.9 | 2 | 3 |

| No. 5-44UNF | 58.7 | 14.4 | 17.3 | 2.2 | 3 |

| No. 6-40UNF | 58.6 | 15.9 | 19.1 | 2.4 | 3 |

| No. 8-36UNF | 58.2 | 17.6 | 21.2 | 3.1 | 3 |

| No.10-32UNF | 62.9 | 19.8 | 23.8 | 3.8 | 3 |

| No.12-28UNF | 67.5 | 22.7 | 27.2 | 4.2 | 3 |

| 1/4-28UNF | 67.1 | 22.7 | 27.2 | 4.8 | 3 |

| 5/16-24UNF | 77 | 26.5 | 31.8 | 6.3 | 5 |

| 3/8-24UNF | 89 | 26.5 | 31.8 | 8 | 5 |

| 7/16-20UNF | 102 | 31.8 | 38.1 | 9 | 5 |

| 1/2-20UNF | 102 | 31.8 | 38.1 | 10 | 5 |

| 9/16-18UNF | 114 | 35.3 | 42.3 | 11.4 | 5 |

| 5/8-18UNF | 127 | 35.3 | 42.3 | 13 | 5 |

| 3/4-16UNF | 133 | 39.7 | 47.6 | 15 | 5 |

| 7/8-14UNF | 133 | 45.4 | 54.4 | 18.5 | 5 |

| 1"-12UNF | 165 | 52.9 | 63.5 | 21 | 5 |

Table 5. W-Type thread (W)

| Thread Specification | A Total Length | B Thread Length | C Shank Dia. | Number of grooves | |

|---|---|---|---|---|---|

| 25 treads | 30 treads (SUS) | ||||

| 1/8 W 40 | 58.7 | 15.9 | 19.1 | 2.2 | 3 |

| 5/32 W 32 | 58.4 | 19.8 | 23.8 | 2.7 | 3 |

| 3/16 W 24 | 63.2 | 26.5 | 31.8 | 3.2 | 3 |

| 1/4 W 20 | 72.4 | 31.8 | 38.1 | 4.6 | 3 |

| 5/16 W 18 | 77 | 35.3 | 42.3 | 6 | 5 |

| 3/8 W 16 | 89 | 39.7 | 47.6 | 7.3 | 5 |

| 7/16 W 14 | 102 | 45.4 | 54.4 | 8.6 | 5 |

| 1/2 W 12 | 102 | 52.9 | 63.5 | 9.5 | 5 |

| 9/16 W 12 | 114 | 52.9 | 63.5 | 10.5 | 5 |

| 5/8 W 11 | 127 | 57.7 | 69.3 | 12 | 5 |

| 3/4 W 10 | 133 | 63.5 | 76.2 | 15 | 5 |

| 7/8 W 9 | 133 | 70.6 | 84.7 | 17 | 5 |

| 1" W 8 | 165 | 79.4 | 95.3 | 20 | 5 |