COLD FORMING ROLL TAPS FOR THREAD ROLLING MACHINES

REFERENCE INFORMATION ABOUT FLUTELESS TAPS

Application and benefits of cold forming taps

Cold forming taps (chipless taps, rolling taps) are recommended to be used when producing threads by plastic deformation (rolling) in parts made of non-ferrous and ferrous metals with high plasticity. These materials include: aluminum and its alloys, copper, brass, bronze with a high copper content, zinc and its alloys, low-carbon and high-plastic stainless and heat-resistant steels. Compared to cutting taps, forming taps have greater strength, provide accurate threads with low surface roughness, and increase thread strength (up to 20%).

High productivity in threading is the main advantage of cold forming taps. They are used for thread forming not only in through holes, but also in blind holes. The thread rolling profile is formed by pressing the tool into the workpiece material and extruding part of the material into the tool cavity.

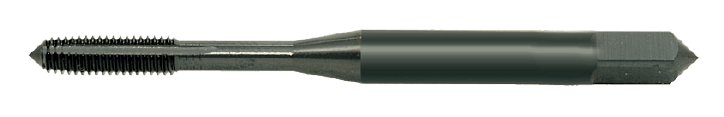

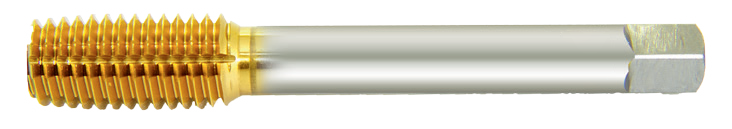

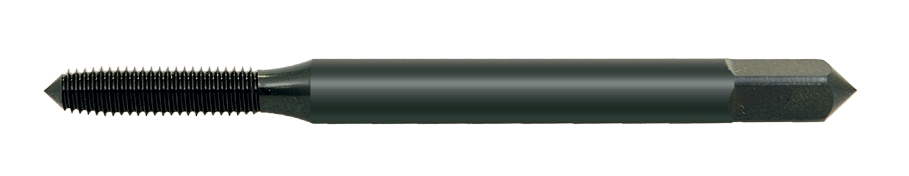

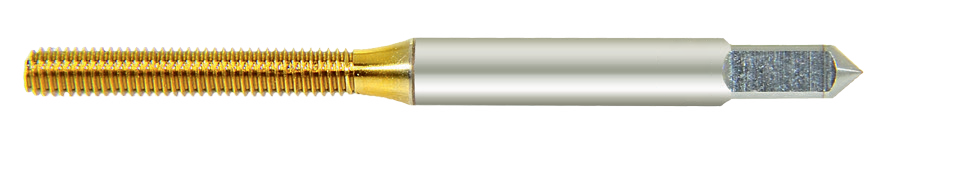

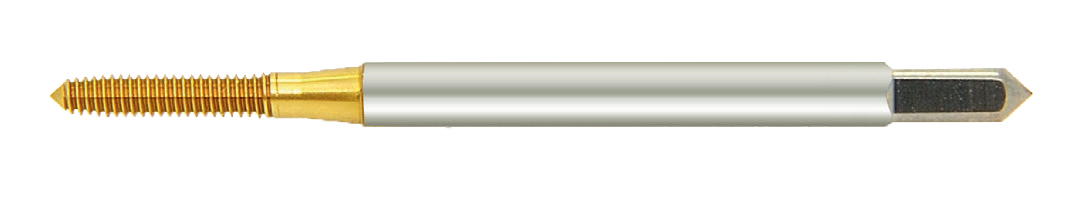

Their main difference from cutting taps is the absence of longitudinal grooves that form cutting edges. In addition, the champfer on these taps is significantly shorter. At the end of the threaded part of the flute taps, there are small symmetrically located coolant grooves.

Benefits of thread forming

- high labor productivity when rolling threads is the main advantage of fluteless taps, they are more productive than conventional cutting taps;

- higher speeds and tool life;

- for use in through and blind holes applications;

- reduced possibility of breakage due to no cutting edges and robust tool construction. Chipless machine taps are much stronger than regular cutting taps, cases of their breakdowns are very rare and scrap of parts due to breakage of taps is almost not observed;

- the service life of the fluteless taps is much longer than usual due to the long thread that can be reground several times;

- guaranteed to provide required accuracy of the thread;

- higher surface quality of the thread;

- ability to handle threads in the holes with 3.5 × D depth, no problems with chip clearance;

- forming taps have higher resistance;

- one type of taps can be used for processing various materials;

- higher tensile strength threads produced due to grain structure following the thread form;

- no chips produced;

- precise uniformity of tapped thread limit;

- excellent rigidity;

- up to 100% stronger thread (higher bearing resistance).

Suitable for wide range materials

- Low carbon steels

- Leaded steels

- Austenitic stainless steels

- Alloy steels

- Aluminium die castings alloys

- Wrought aluminium alloys

- Zinc die casting alloys

- Copper and copper alloys

Fluteless taps RH class (thread limit) selection

Fluteless taps are described by the RH limit system. The limits are established in increments of 12.7µm. The RH class of fluteless taps is determined by the tolerances (1, 2, 3B, 2B, etc.) for the internal thread.

| Thread Specification | Pitch | TAP THREAD TOLERANCE | |||||

|---|---|---|---|---|---|---|---|

| Class 1 internal thread | Class 2 internal thread | increased accuracy (*) | |||||

| Class 2 +0.02 ~ +0.03 | Class 2 +0.04 ~ +0.05 | ||||||

M3 M4 M4.5 M5 M5.5 M3 M3.5 | 0.5 0.35 | RH 3 3 | RH 4 4 | RH 5 5 | RH 6 6 | RH 8 7 | RH 9 8 |

M3.5 | 0.6 | RH 3 | RH 4 | RH 5 | RH 6 | RH 7 | RH 8 |

M4 | 0.7 | RH 4 | RH 5 | RH 6 | RH 7 | RH 9 | RH 10 |

M5 | 0.8 | RH 4 | RH 5 | RH 6 | RH 7 | RH 9 | RH 10 |

M6 M4 M4.5 M6 | 1 0.75 | RH 4 4 | RH 6 5 | RH 7 6 | RH 8 7 | RH 9 8 | RH 10 9 |

M7 M8 M9 M10 M11 | 1 0.75 | RH 4 5 | RH 6 6 | RH 7 7 | RH 8 8 | RH 9 9 | RH 10 10 |

M10 M11 M12 M8 M9 M10 M12 | 1 1.25 | RH 5 5 | RH 6 6 | RH 7 7 | RH 8 8 | RH 9 9 | RH 10 10 |

M10 M11 M12 M12 | 1.5 1.75 | RH 5 5 | RH 6 7 | RH 7 8 | RH 8 9 | RH 9 10 | RH 10 11 |

M14 M15 M16 M17 M18 M20 M22 M24 | 1 1 | RH 5 5 | RH 8 8 | RH 9 9 | RH 10 10 | RH 11 11 | RH 12 12 |

M14 M15 M16 M18 M20 M22 M24 | 1.5 1.5 | RH 5 6 | RH 8 9 | RH 9 10 | RH 10 11 | RH 11 12 | RH 12 13 |

M14 M16 M17 | 2 1.5 | RH 6 9 | RH 9 10 | RH 10 11 | RH 11 12 | RH 12 13 | RH 13 14 |

M18 M20 M22 M18 M20 M22 | 2 2.5 | RH 6 6 | RH 10 10 | RH 11 11 | RH 12 12 | RH 13 13 | RH 14 14 |

M24 M24 | 2 3 | RH 6 8 | RH 10 11 | RH 11 12 | RH 12 13 | RH 13 14 | RH 14 15 |

| Thread Specification | threads per inch (25.4 mm) | TAP THREAD TOLERANCE | |||||

|---|---|---|---|---|---|---|---|

| Class 3B internal thread | Class 2B internal thread | increased accuracy (*) | |||||

Class 2B +0.02 ~ +0.03 | Class 2B +0.04 ~ +0.05 | ||||||

No.5 | 44 | RH 3 | RH 4 | RH 5 | RH 6 | RH 7 | RH 8 |

No.4 No.5 No.6 | 40 | RH 3 | RH 4 | RH 5 | RH 6 | RH 7 | RH 8 |

No.8 | 36 | RH 4 | RH 5 | RH 6 | RH 7 | RH 8 | |

No.6 No.8 No.10 | 32 | RH 4 | RH 5 | RH 6 | RH 7 | RH 8 | |

No.10 No.12 No.12 | 24 28 | RH 4 4 | RH 5 | RH 6 5 | RH 7 6 | RH 8 8 | RH 9 9 |

U 1/ 4 | 20 28 | RH 4 4 | RH 5 | RH 6 5 | RH 7 6 | RH 8 7 | RH 9 8 |

5/16 | 18 24 | RH 5 5 | RH 6 | RH 7 6 | RH 8 7 | RH 9 8 | RH 10 9 |

3/ 8 | 16 24 | RH 5 5 | RH 6 | RH 7 6 | RH 8 7 | RH 9 8 | RH 10 9 |

7/16 | 14 20 | RH 5 5 | RH 6 6 | RH 7 7 | RH 8 8 | RH 9 9 | RH 10 10 |

1/ 2 | 13 20 | RH 6 5 | RH 7 6 | RH 8 7 | RH 9 8 | RH 10 9 | RH 11 10 |

9/16 | 12 18 | RH 8 7 | RH 9 8 | RH 10 9 | RH 11 10 | RH 12 11 | RH 13 12 |

5/ 8 | 11 18 | RH 8 7 | RH 10 8 | RH 11 9 | RH 12 10 | RH 13 11 | RH 14 12 |

3/ 4 | 10 16 | RH 9 7 | RH 11 9 | RH 12 10 | RH 13 11 | RH 14 12 | RH 15 13 |

7/ 8 | 9 14 | RH 9 8 | RH 11 10 | RH 12 11 | RH 13 12 | RH 14 13 | RH 15 14 |

1” | 8 12 | RH 10 9 | RH 12 11 | RH 13 12 | RH 14 13 | RH 15 14 | RH 16 15 |

(*) Increased tap precision with high demands on internal thread precision.

(*) Actual parameters of accuracy when processing materials may differ from the reference depending on specific materials and processing conditions.

Tables 1 and 2 define the tap tolerance in 12.7 µm (0.0005 ") increments.

upper limit = 12.7 µm × n (n = RH number)

lower limit = upper limit - 12.7 µm

Example: RH limits RH6

upper limit: 12.7 × 6 = 77 µm,

lower limit: 77 µm - 12.7 µm (round to 13 µm) = 64 µm

Calculating Tap Drill Sizes for Forming Taps

Tapping drill formula for fluteless taps 1

dN = D - P х 0.45

dN - drill size

D - tap diameter

P - thread pitch

Tapping drill formula for fluteless taps 2

dN = D - 0.2 × P - 0.00403 × P × f1 + 0.0127 × n

dN - drill size

D - tap diameter

P - thread pitch

f1 = 90 % - percentage of thread engagement (in %)

n = RH number of Tap

Example - internal thread M10 × 1.5 RH7 Class of Fit 2

dN = 10-0.2×1.5-0.00403×1.5×90+0.0127×7 = 9.24 mm

Selection of cutting fluid

| Work Material | Cutting Fluid |

|---|---|

| Aluminum, die-cast aluminum, Zinc alloys, zinc casting | water-soluble salts, oil-soluble non-greasy cutting fluid |

| copper, brass | oil-based water-soluble cutting fluid, water-soluble cutting fluid |

| soft steel and soft magnetic steel, free-cutting steel | water-soluble sulfurized oil, sulfur base oil |

| ordinary steel, mild steel, stainless steel (hardness HRC20 or less) | sulfur base oil, water-soluble sulfurized oil and sulfur-based salts |

Tapping Speed Selection

| Working Material | Cutting Speed m/min |

|---|---|

| Aluminum, copper, soft brass | 20 ~ 30 |

| Aluminum, cast aluminum, lead alloys, zinc casting, mild steel, brass, bronze, soft magnetic steels | 12 ~ 20 |

| Plain steel (hardness HRC 20 or less), mild steel, stainless steel | 5 ~ 12 |