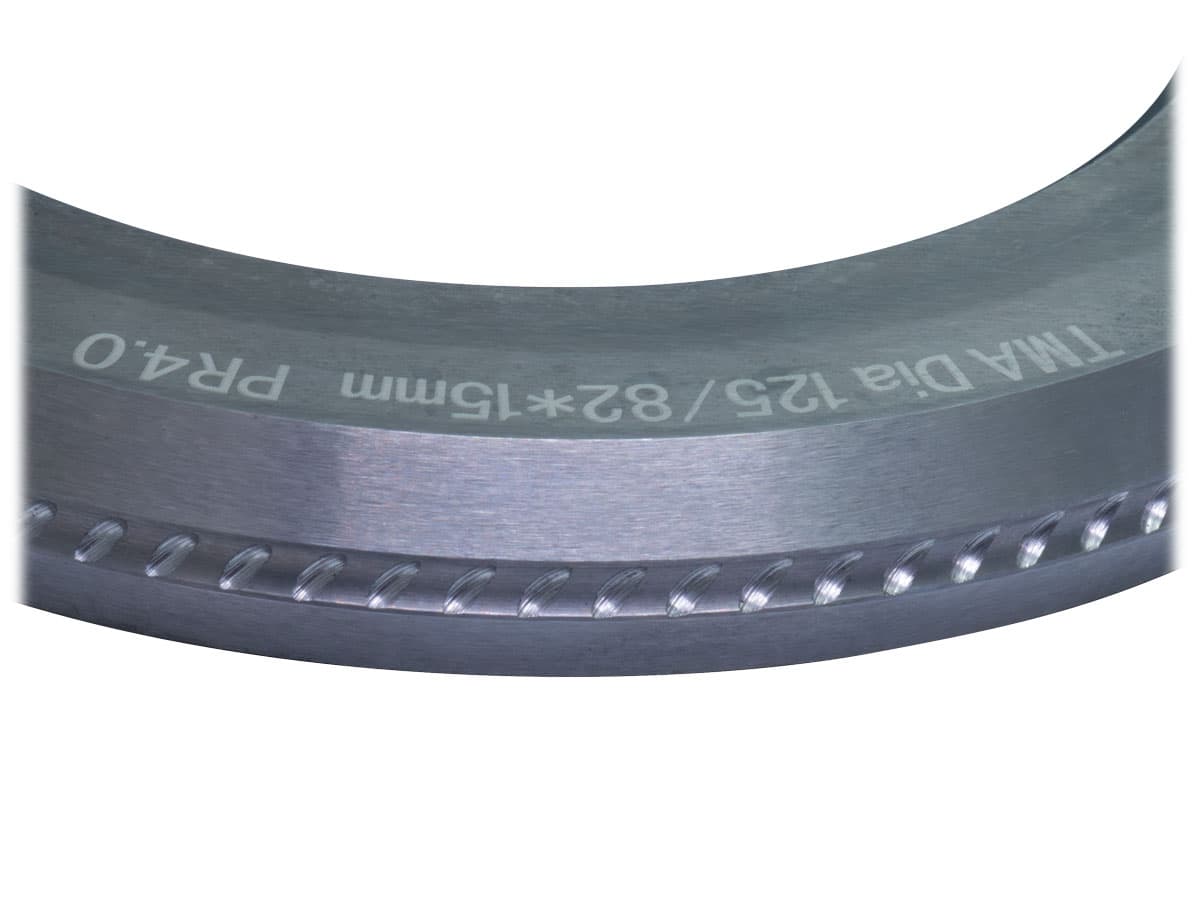

Tungsten Carbide Rolls For Wire Ribbing

TMA TUNGSTEN CARBIDE FORMING AND PROFILING ROLLS

We produce tungsten carbide forming and profiling rollers for the production of rebars with a profile according to the requirements of standards: SFS 1300, DIN 488, AT/2010-02-2641/3, ITB No AT-15-9480/2015, NEN6008-2008, BRL 0501-2010, NS 3576, GOST R 52544-2006.

Tungsten carbide rolls, also referred to as tungsten carbide cold rolls, are extensively employed in the construction reinforcement field to produce smooth or ribbed wire for the construction field according to different standards and demands of the market.

Benefits of Using Tungsten Carbide Forming and Profiling Rolls:

Extended Durability: Tungsten carbide rolls have the advantage of lasting up to 50 times longer than conventional, hardened tool steel rolls. This increased durability leads to cost savings and minimizes downtime for roll replacements.

Enhanced Dimensional Precision and Surface Finish: Tungsten carbide rolls offer high dimensional precision, resulting in accurate and consistent wire rod dimensions. These rolls also contribute to improved surface finish, ensuring smooth and polished wire surfaces.

Improved Strength for Cold Rolling: Tungsten carbide rolls provide enhanced strength for the cold rolling process of wire rods. This results in durable and reliable wire products with superior mechanical properties.

Enhanced Product Performance: The use of tungsten carbide rolls ensures guaranteed product performance, allowing for more efficient operation and significant time savings.

Effective Wear Problem Solution: Tungsten carbide rolls effectively address excess wear issues that may arise in any section of the mill's rolls. This helps maintain optimal operational efficiency and reduces maintenance requirements. Tungsten carbide rolls are manufactured using virgin raw materials, offering a high level of hardness and exceptional wear resistance. This ensures prolonged roll life and reduces the frequency of roll replacements, leading to cost savings and improved production efficiency.

Reduced Changeovers: Compared to hardened tool steel rolls, tungsten carbide rolls experience less excessive wear, resulting in fewer required changeovers. This contributes to improved productivity and reduced downtime.

Non-Destructive Ultrasonic Flaw Detection: Tungsten carbide rolls undergo non-destructive ultrasonic flaw detection to ensure their quality and reliability. This process helps identify and eliminate any sand holes, pores, cracks, or inclusions that could potentially affect the functionality or performance of the rolls.

Ideal for High Volume Production: When a high footage/tonnage is required from a specific size, tungsten carbide rolls should be seriously considered. Their robustness and longevity make them ideal for demanding production requirements.

Overall, the utilization of tungsten carbide rolls offers numerous advantages, including extended roll life, improved productivity, and cost-effectiveness, making them a valuable choice for various industrial applications. Using tungsten carbide rolls in the wire rod cold rolling process provides significant benefits such as improved dimensional precision, excellent surface finish, enhanced strength, and exceptional wear resistance. Additionally, the implementation of non-destructive testing techniques ensures the reliability and integrity of the rolls, further enhancing their overall performance.

Reinforcing bars according to DIN 488

| Nominal Dimension | Informative Dimension | Nominal Cross Section Area | Theoretical Weight | Steel Grades | Lenght | |||

|---|---|---|---|---|---|---|---|---|

| d | c | h | D | b | S | |||

| mm | mm | mm2 | kg/m | m | ||||

| 6 | 5.0 | 0.6 | 7.2 | 0.6 | 28.3 | 0.25 | B500A | 6, 12 |

| 8 | 5.7 | 0.7 | 9.4 | 0.8 | 50.3 | 0.42 | B500B, B500A | |

| 10 | 6.5 | 0.8 | 11.6 | 1.0 | 78.5 | 0.62 | B500B | 6, 12, 14 |

| 12 | 7.2 | 1.0 | 14.0 | 1.2 | 113.0 | 0.89 | ||

| 14 | 8.4 | 1.1 | 16.6 | 1.4 | 154.0 | 1.23 | ||

| 16 | 9.6 | 1.2 | 18.8 | 1.6 | 201.0 | 1.60 | ||

| 18 | 10.5 | 1.3 | 21.0 | 1.8 | 254.0 | 2.00 | 12, 14 | |

| 20 | 11.5 | 1.5 | 23.2 | 2.0 | 314.0 | 2.47 | ||

| 22 | 13,0 | 1.7 | 25.4 | 2.2 | 380.0 | 2.98 | ||

| 25 | 14.5 | 1.9 | 28.8 | 2.5 | 491.0 | 3.85 | ||

| 28 | 15.5 | 2.1 | 32.0 | 2.8 | 616.0 | 4.83 | ||

| 32 | 16.5 | 2.2 | 37.0 | 3.2 | 804.0 | 6.31 | ||