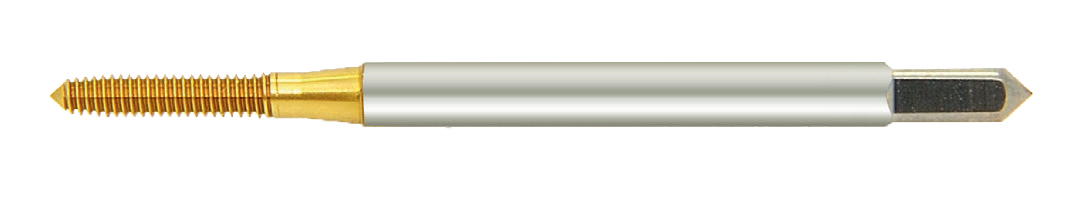

COLD FORMING ROLL TAPS FOR THREAD ROLLING MACHINES

TiN COATED ROLL TAPS FOR IT PARTS

Fluteless taps produce threads by deforming the material, thus without any chips. They are suitable for blind and through holes, and their field of application has grown wider, including now aluminum, steel and stainless.

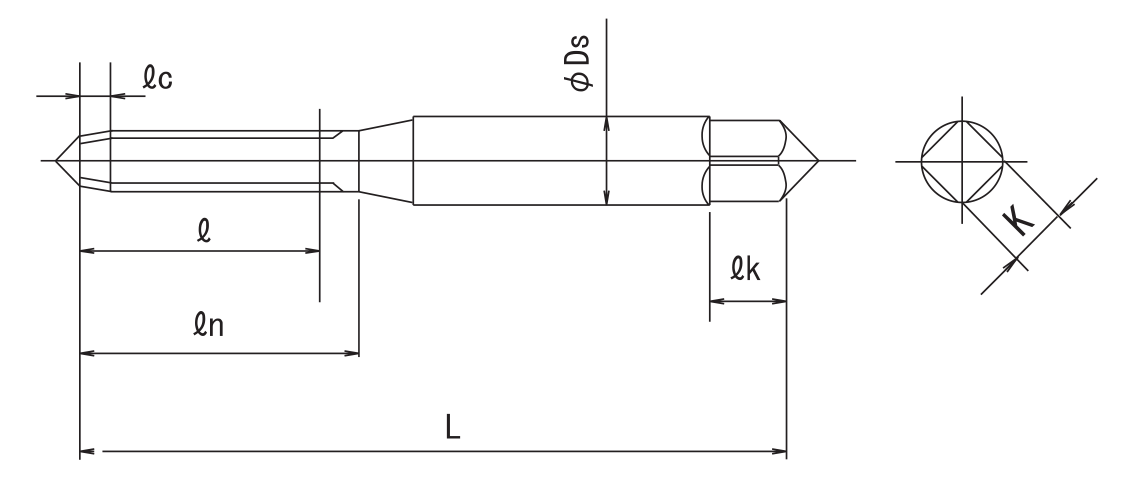

Outlook & Drawing

Application and Features of Fluteless Tap

Suitable for ferrous materials such as low carbon steels, medium carbon steels, high carbon steels

Tool Material Type: Vanadium-containing High-Speed Steel (HSSE).

Surface treatment: TiN (Titanium Nitride).

- Achieves high-quality, burr-less tapping and controlling the minor diameter geometry of internal thread

- For IT industry, the thread size is below M3

- Wider tapping application range with the ability for high speed tapping

- Quite fit for aluminum alloy casting and zinc casting application

Attention! Threading with fluteless tap is only applicable for stringy materials.

Work material and recommended tapping speed

| Work Material | Blind hole | Through hole | suitable cutting speed (m/min) | Work Material | Blind hole | Through hole | suitable cutting speed (m/min) |

|---|---|---|---|---|---|---|---|

| Low Carbon Steels ~C0.25 | Excellent | Excellent | 8~13 | Brass castings/Brass Bsc.Bs | Good | Good | 7~12 |

| Medium Carbon Steels C0.25~C0.45 | Excellent | Excellent | 7~10 | Bronze PB | Good | 10~20 | |

| High Carbon Steels C0.45~ | Excellent | Excellent | 5~8 | Aluminum Rolled AL | Good | Good | 7~12 |

| Alloy steels SCM | Good | Good | 5~8 | Aluminum alloy castings AC ADC | Good | 10~15 | |

| Hardened Steels HRC25~45 | Good | Good | - | Magnesium alloy casting MC | - | ||

| Stainless Steels SUS | Excellent | Excellent | 5~10 | Zinc castings ZDC | Good | Excellent | 7~12 |

| Cast Steel SC | Good | - | Titanium Alloys Ti-AL | - | |||

| Cast Iron FC | Good | - | Nickel alloys Inocorel | - | |||

| High Tension Cast Iron FCD | - | Thermosetting Plastic Epoxy | - | ||||

| Cooper Cu | Good | Good | 7~12 | Thermoplastic PVC Nylon POM | - |

Lubrication

| Cutting Fluid | Work Material |

|---|---|

| NON-WATER SOLUBLE | Carbon steels (low,medium,high), Alloy steels, Hardened Steels, Stain steels, Cast steels, Cast iron, Ductile cast, Cooper, Brass, Brass casting, Bronze, Aluminum Rolled, Aluminum alloy casting, Masnesium alloy casting, Zinc alloy casting |

| WATER SOLUBLE | Carbon steels (low,medium,high), Alloy steels, Hardened Steels, Stain steels, Cast steels, Cast iron, Ductile cast, Cooper, Brass, Brass casting, Bronze, Aluminum Rolled, Aluminum alloy casting, Masnesium alloy casting, Zinc alloy casting, Thermosetting Plastic, Thermoplastic |

| SEMI-DRY | Cast iron, Ductile cast, Brass, Brass casting, Thermosetting Plastic |

| DRY | Cast iron, Brass, Brass casting, Thermosetting Plastic |

Ordering of TiN Coated Roll Taps for IT Parts

| RG NO. | Thread Size | TAP Limit | Chamfer (lc) | Total Length (L) | Thread Length (l) | Shank Dia. (Ds) |

|---|---|---|---|---|---|---|

| 160230 | M1 X 0.25 | RH3 | P | 32 | 5.5 | 3 |

| 160231 | M1 X 0.25 | RH3 | B | 32 | 5.5 | 3 |

| 160240 | M1 X 0.25 | RH4 | P | 32 | 5.5 | 3 |

| 160241 | M1 X 0.25 | RH4 | B | 32 | 5.5 | 3 |

| 160250 | M1 X 0.25 | RH5 | P | 32 | 5.5 | 3 |

| 160251 | M1 X 0.25 | RH5 | B | 32 | 5.5 | 3 |

| 160330 | M1.2 X 0.25 | RH3 | P | 32 | 5.5 | 3 |

| 160331 | M1.2 X 0.25 | RH3 | B | 32 | 5.5 | 3 |

| 160340 | M1.2 X 0.25 | RH4 | P | 32 | 5.5 | 3 |

| 160341 | M1.2 X 0.25 | RH4 | B | 32 | 5.5 | 3 |

| 160350 | M1.2 X 0.25 | RH5 | P | 32 | 5.5 | 3 |

| 160351 | M1.2 X 0.25 | RH5 | B | 32 | 5.5 | 3 |

| 160440 | M1.4 X 0.3 | RH4 | P | 36 | 7 | 3 |

| 160441 | M1.4 X 0.3 | RH4 | B | 36 | 7 | 3 |

| 160450 | M1.4 X 0.3 | RH5 | P | 36 | 7 | 3 |

| 160451 | M1.4 X 0.3 | RH5 | B | 36 | 7 | 3 |

| 160540 | M1.6 X 0.35 | RH4 | P | 36 | 8 | 3 |

| 160541 | M1.6 X 0.35 | RH4 | B | 36 | 8 | 3 |

| 160550 | M1.6 X 0.35 | RH5 | P | 36 | 8 | 3 |

| 160551 | M1.6 X 0.35 | RH5 | B | 36 | 8 | 3 |

| 160740 | M1.7 X 0.35 | RH4 | P | 36 | 8 | 3 |

| 160741 | M1.7 X 0.35 | RH4 | B | 36 | 8 | 3 |

| 160750 | M1.7 X 0.35 | RH5 | P | 36 | 8 | 3 |

| 160751 | M1.7 X 0.35 | RH5 | B | 36 | 8 | 3 |

| 160760 | M1.7 X 0.35 | RH6 | P | 36 | 8 | 3 |

| 160761 | M1.7 X 0.35 | RH6 | B | 36 | 8 | 3 |

| 160830 | M2 X 0.4 | RH3 | P | 42 | 8 | 3 |

| 160831 | M2 X 0.4 | RH3 | B | 42 | 8 | 3 |

| 160840 | M2 X 0.4 | RH4 | P | 42 | 8 | 3 |

| 160841 | M2 X 0.4 | RH4 | B | 42 | 8 | 3 |

| 160850 | M2 X 0.4 | RH5 | P | 42 | 8 | 3 |

| 160851 | M2 X 0.4 | RH5 | B | 42 | 8 | 3 |

| 160860 | M2 X 0.4 | RH6 | P | 42 | 8 | 3 |

| 160861 | M2 X 0.4 | RH6 | B | 42 | 8 | 3 |

| 160870 | M2 X 0.4 | RH7 | P | 42 | 8 | 3 |

| 160871 | M2 X 0.4 | RH7 | B | 42 | 8 | 3 |

All table dimensions in mm.