TMA COLD HEADING DIES

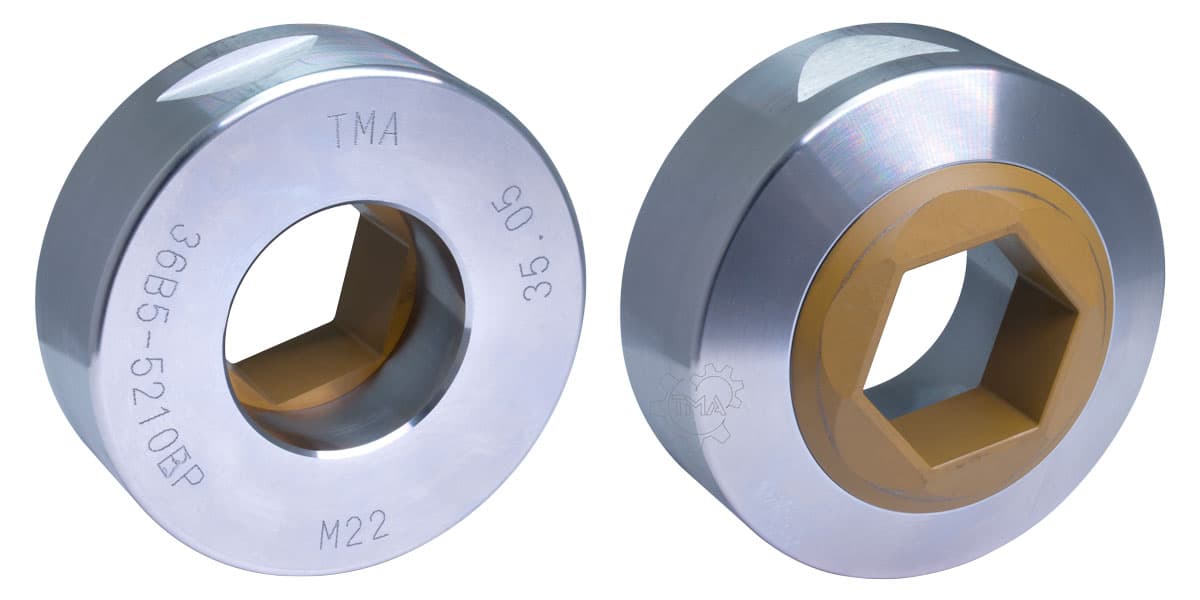

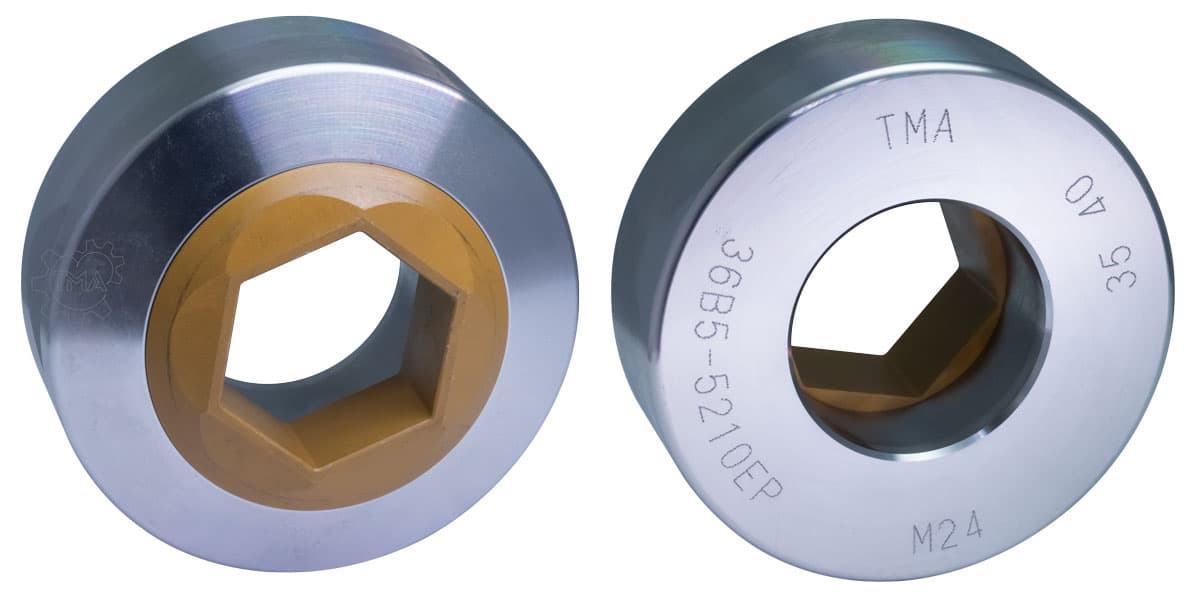

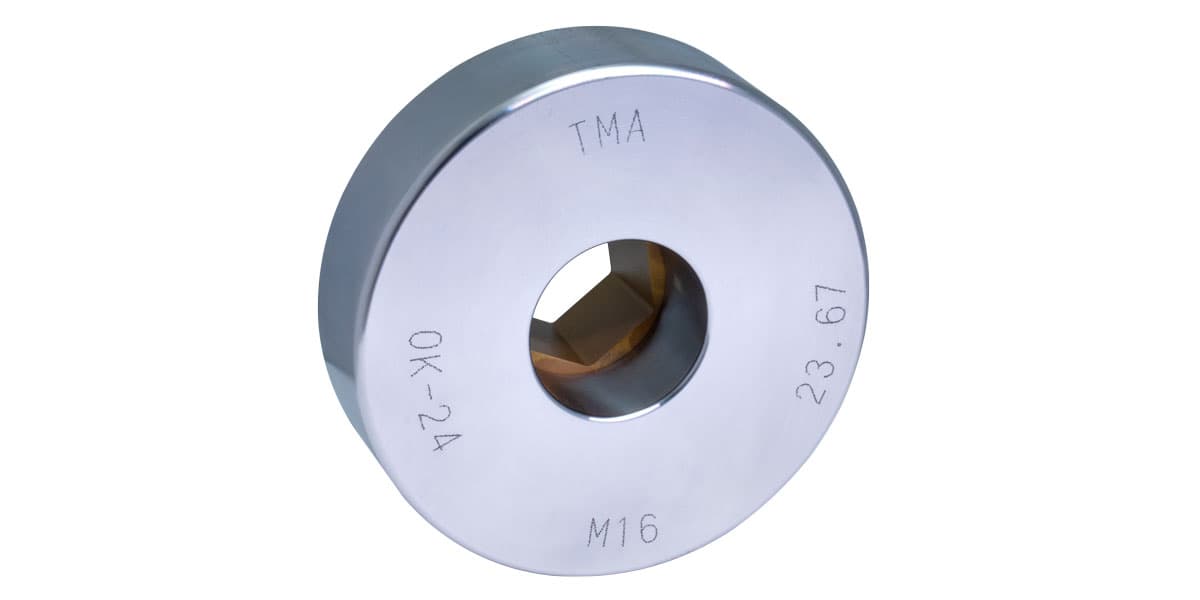

Cold Forming Trimming Die

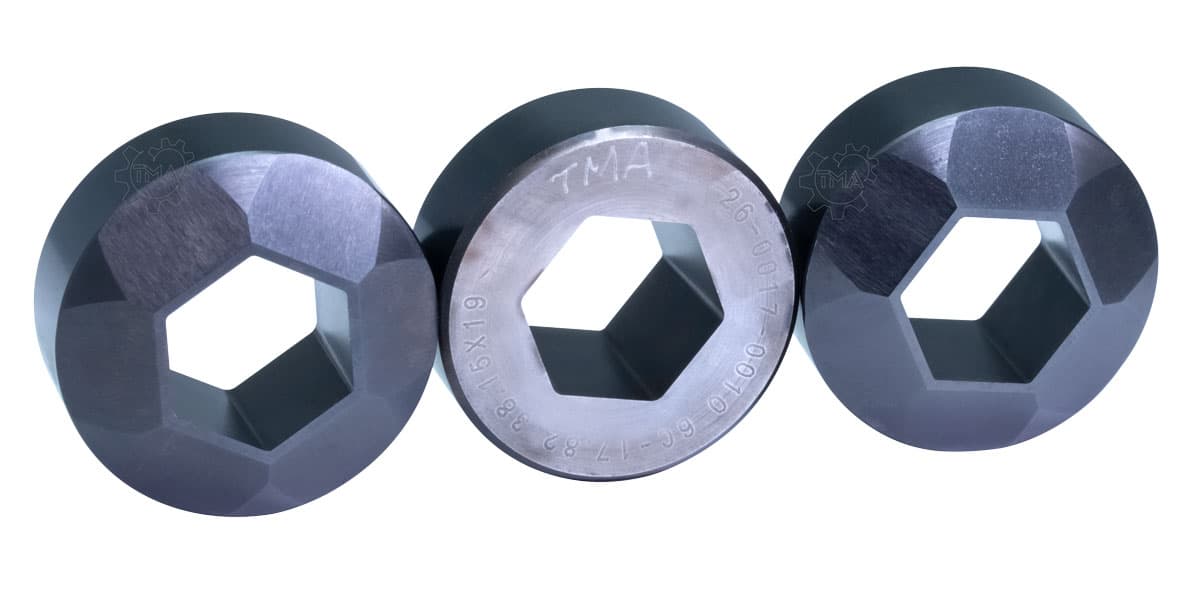

In case of cold heading bolts on automatic machines hexagonal, square and close to them heads are usually made out by trimming a barrel-shaped set of metal. Technological operation of obtaining the head is carried out in a trimming die, usually located in a block of punches, through which the metal set for the head is pushed by a trimming punch with a pusher. Cutting dies are highly loaded parts of tooling and their consumption in mass production of bolts is very high.

Depending on the complexity of the part, during the cold heading process, the trimming operation can be performed several times: to trim the hexagon on the bolt head and to trim the head flange.

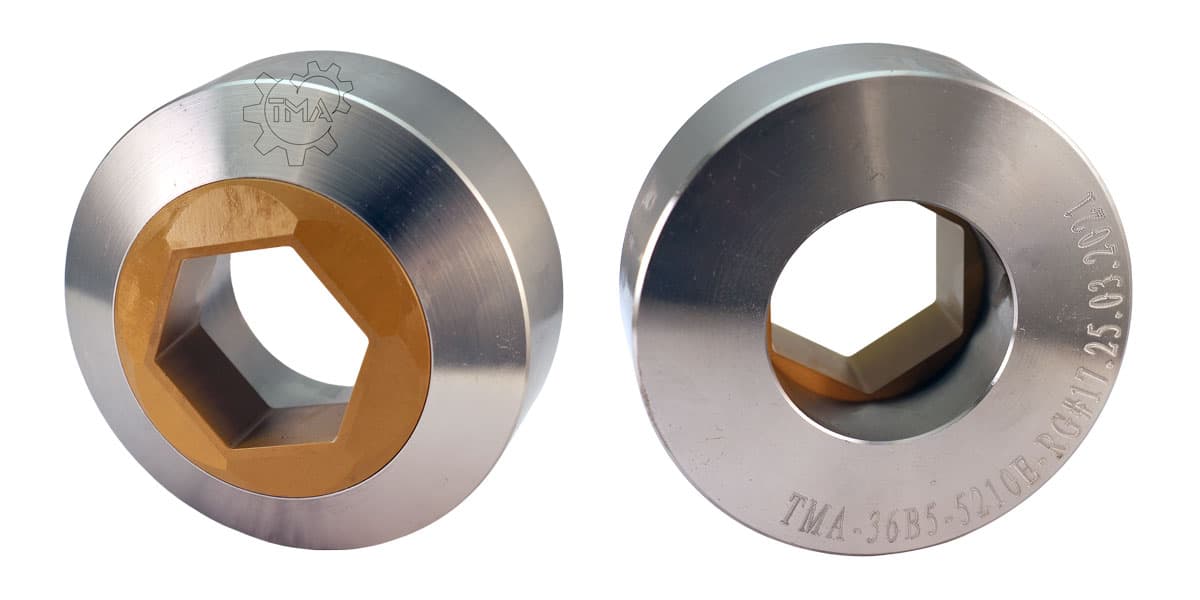

From the point of view of the choice of the manufacturing method, the trimming dies are parts with a through relief axial cavity that has a slope. They are installed in the body without interference, which allows for quick replacement.

- Trimming dies (cutting dies) are made in accordance with the individual requirements of the customer.

- Excellent lifetime of the cutting dies contributes to production savings.

- The average life of the trimming die is 60,000 strokes on the reference product M8 screw made of SCM435 alloy wire.

- Alloy MD-4 cutting dies for bolts, nuts and stainless steel special parts have a life of 40,000 strokes.

| Model | Workpiece size | Outer dimension | Cross section | ||

|---|---|---|---|---|---|

| D | L | B | |||

| RG-5001-01 | M5 | 30 | 20 | 7.80 | +0.05 |

| RG-5001-02 | M6 | 30 | 20 | 9.80 | +0.05 |

| RG-5001-03 | 1/4UNC | 30 | 20 | 10.92 | +0.05 |

| RG-5001-04 | 5/16UNC | 35 | 23 | 12.45 | +0.07 |

| RG-5001-05 | M8 | 35 | 23 | 12.75 | +0.07 |

| RG-5001-06 | 3/8UNC | 35 | 23 | 14.05 | +0.07 |

| RG-5001-07 | 7/16UNC | 42 | 23 | 15.60 | +0.07 |

| RG-5001-08 | M10 | 42 | 23 | 16.75 | +0.07 |

| RG-5001-09 | M12 | 45 | 28 | 18.70 | +0.1 |

| RG-5001-10 | 1/2UNC | 45 | 28 | 18.75 | +0.1 |

| RG-5001-11 | M14 | 45 | 28 | 21.75 | +0.1 |

| RG-5001-12 | 5/8UNC | 59 | 32 | 23.50 | +0.1 |

| RG-5001-13 | M16 | 59 | 32 | 23.75 | +0.1 |

| RG-5001-14 | M18 | 59 | 32 | 26.75 | +0.1 |

| RG-5001-15 | 5/8UNC | 60 | 40 | 23.50 | +0.1 |

| RG-5001-16 | M16 | 60 | 40 | 23.75 | +0.1 |

| RG-5001-17 | M18 | 60 | 40 | 26.75 | +0.1 |

| RG-5001-18 | M20 | 60 | 40 | 29.75 | +0.1 |

| RG-5001-19 | 5/8UNC | 64 | 32 | 23.50 | +0.1 |

| RG-5001-20 | M16 | 64 | 32 | 23.75 | +0.1 |

| RG-5001-21 | M18 | 64 | 32 | 26.75 | +0.1 |

| RG-5001-22 | M20 | 64 | 32 | 29.75 | +0.1 |

| RG-5001-23 | A325 4/3 | 64 | 32 | 30.90 | +0.1 |

| RG-5001-24 | M20 | 74 | 40 | 29.75 | +0.1 |

| RG-5001-25 | A325 4/3 | 74 | 40 | 30.90 | +0.1 |

| RG-5001-26 | 7/8UNC | 89 | 40 | 32.80 | +0.12 |

| RG-5001-27 | A325 7/8 | 89 | 40 | 35.60 | +0.12 |

| RG-5001-28 | M24 | 89 | 40 | 35.75 | +0.12 |

| RG-5001-29 | 1"UNC | 89 | 40 | 37.50 | +0.12 |

| RG-5001-30 | A325 1" | 89 | 40 | 40.40 | +0.12 |

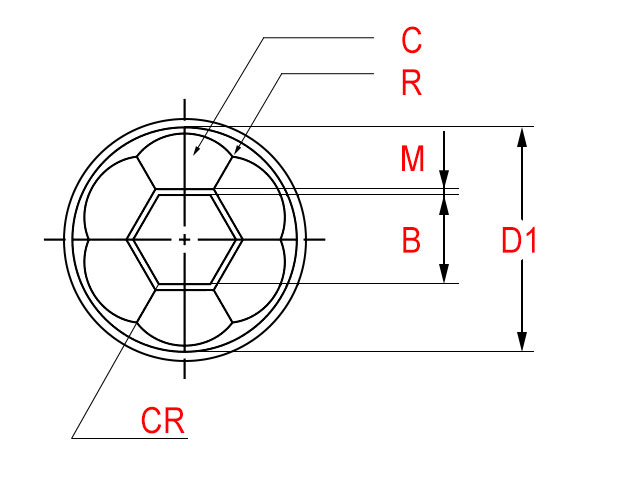

C - clearance

R - rake face

M - width of land

B - width of across flats

CR - corner radius

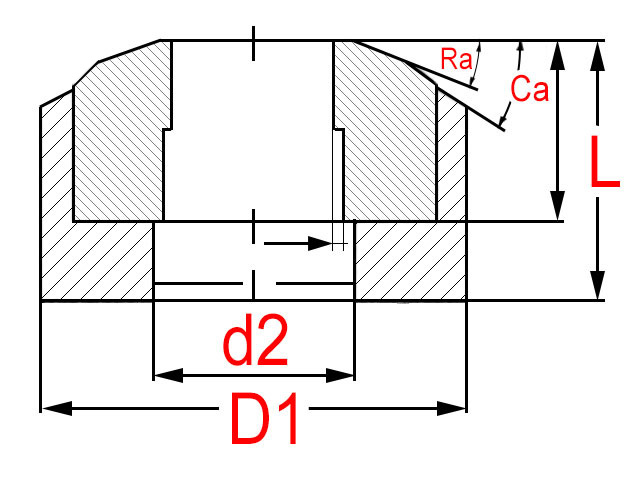

D1 - outled diameter

d2 - clearance hole diameter

L - height

Ca - clearance angle

Ra - rake angle