TUNGSTEN CARBIDE PRECISION MOLD AND DIE

TUNGSTEN CARBIDE TOOLS

Our company is one of the most competent and competitive suppliers of hard carbide material in Asia; devoting its excellence in servicing global market, focusing on the material research and development, and in turn establishing global technology platform. We have an ability to offer customer solution with vertically integrated production process control from powder to preformed parts, and high precision mold and die offerings.

OUR INDUSTRY CHAIN

Tungsten

Ore

Ammonium Paratungstate

Tungsten Powder

Ready to

Press Powder

Tungsten Carbide

Industrial

Wear Parts

Rods

Wood and

Stone

Cutting Tools

Tungsten Ore

Ammonium Paratungstate

Tungsten Powder

Ready to Press Powder

Tungsten Carbide

Industrial Wear Parts

Rods

Wood and Stone

Cutting Tools

Our values

- We provide the best solutions for our customers’ success.

- We enable our customer to achieve outperformance.

- Strengthening competitiveness of our customers is our long-term goal.

- Training & continuous Learning. Nurturing talents for sustainable long-term growth.

Core Competency

- High-end equipment

- Stable quality

- On-time delivery

- Comprehensive service

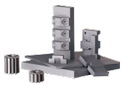

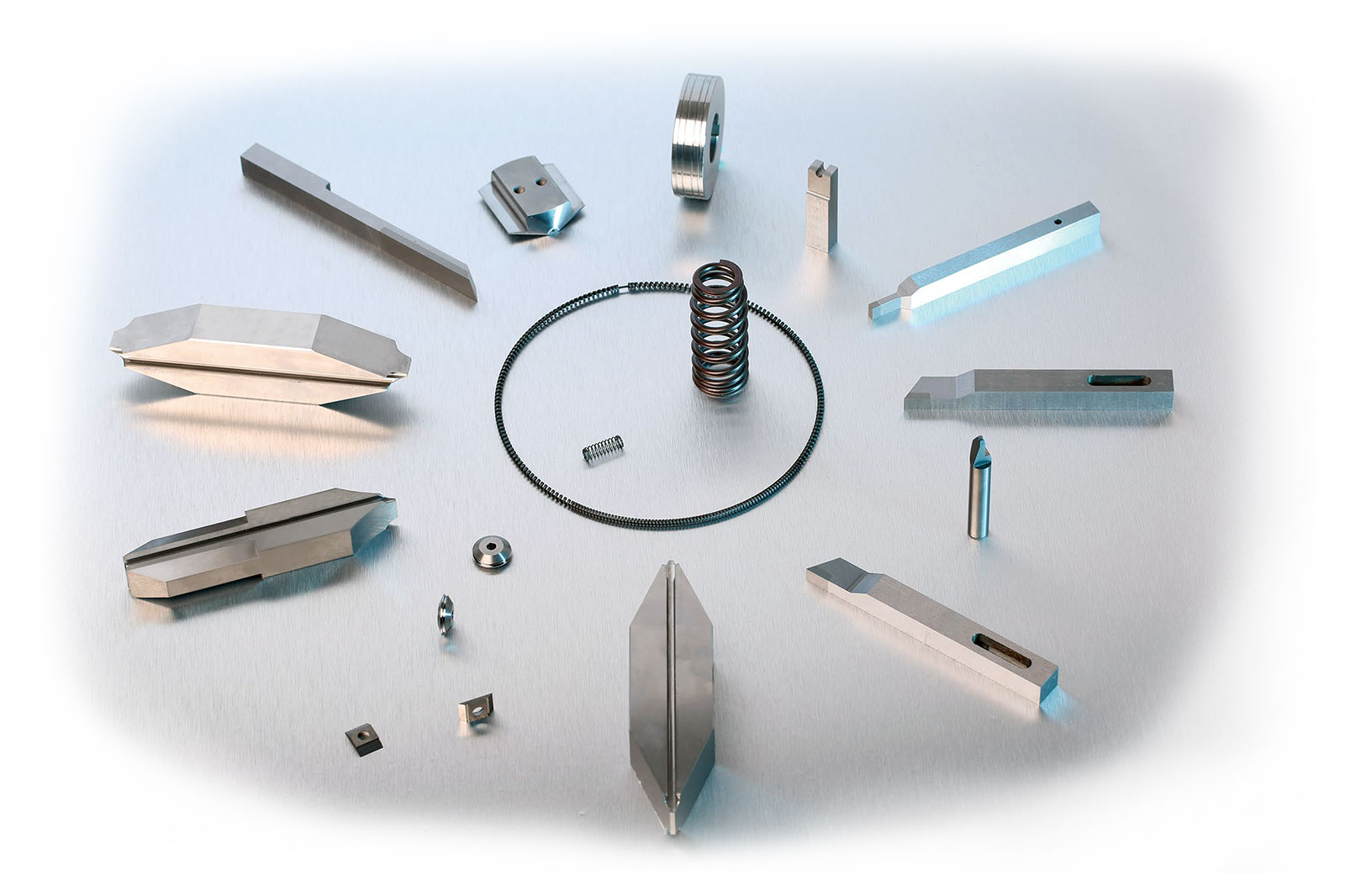

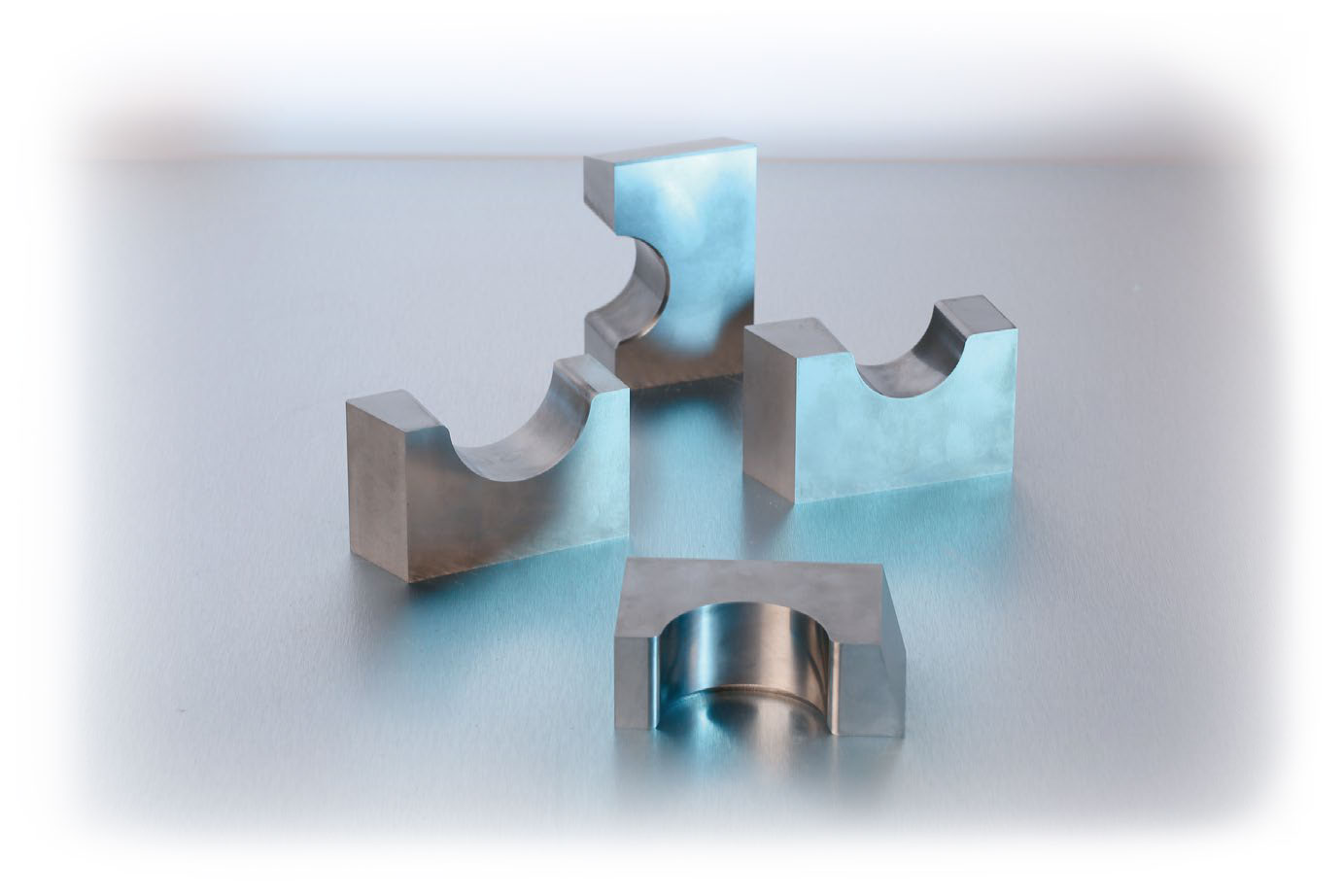

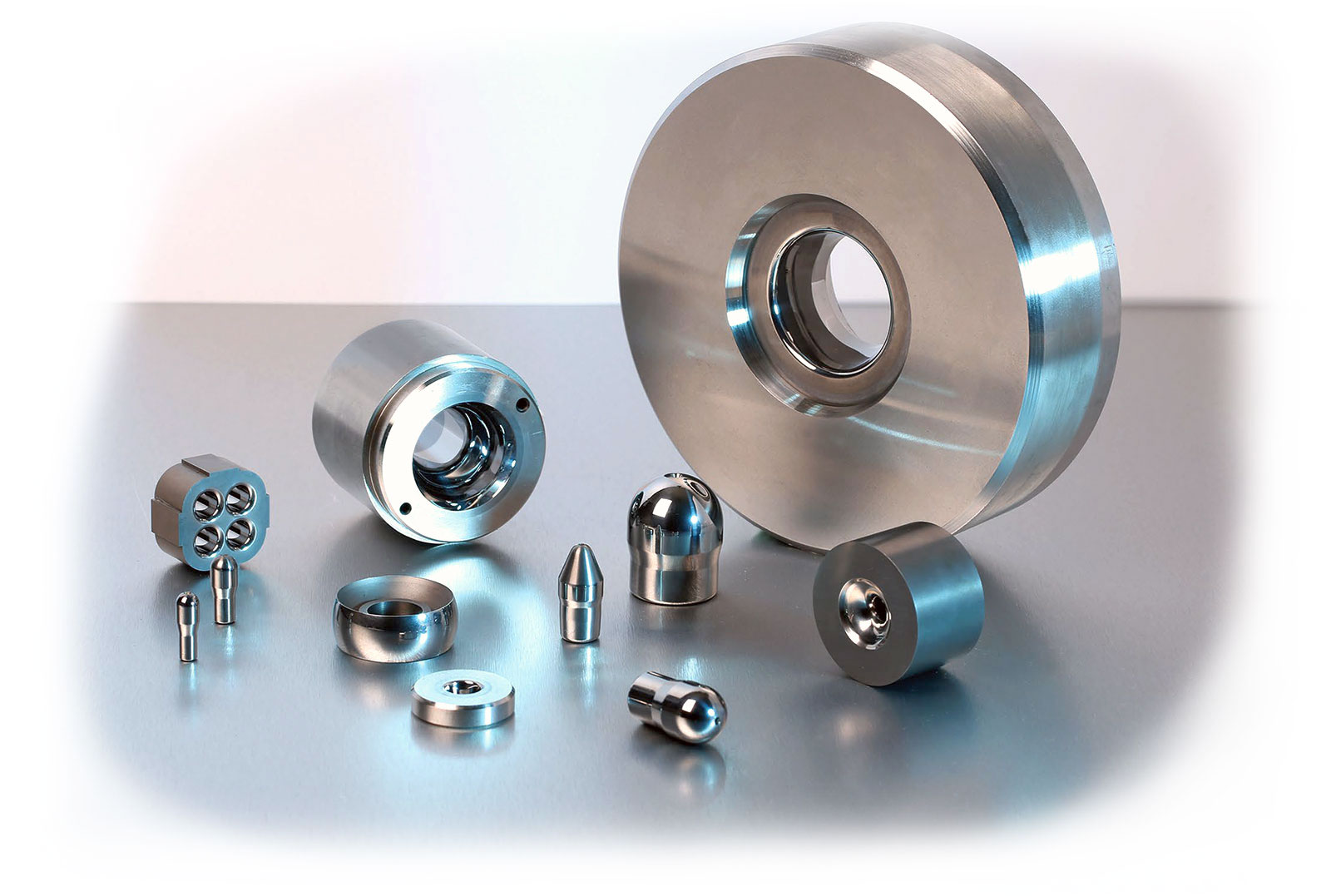

Molds and Dies Production

Our Production Center of Molds and Dies with its in-depth knowledge of tungsten carbide, assists customers accurately and selects materials based on their application, with higher tool life. Products are widely used in industries such as metal forming, oil, natural gas, seal ring, shaft sleeve, all kinds of wheels, shears, and automobile parts, used in all types of industries. In the recent years, with in-depth research and development in various industries, we constantly introduce new technologies and increase investment in high-end production equipment, devoting to build Asia's largest tungsten carbide mold and die machining center.

| Mold type | Description | Application industry |

|---|---|---|

| Forging molds for automotive components is processed by hot forging, cold forging, and precision forging process. | ||

| Fastening products for automotive, construction, home appliance, aerospace and other industries. | ||

| A tool for precision process spring, which is used in automotive and high-end electronic products. | ||

| A tool for process bearing products, which include the forming of bearing ball, bearing wheel and ring. | ||

| Various precision gear parts for automotive, motorcycles and electronic products. | ||

Roller Roller | Various roller products for wire forming and frons portation of production. | |

| Tools apply in the diameter reduction and forming of wire and tube. | ||

| High precision mold for the photovoltaic industry, which apply in processing of aspherical glass lens for mobile phone, camera, security monitoring. | ||

| Tools for seamless tin forming provide solution for punching, stretching and retracting. |

| WC+Other (±0.5%) | Co (±0.5%) | Density (g/cm3) | Hardness (HRA)±0.5 | T.R.S. (kfg/mm2) | Impact Strength (kgf-m/cm2) | |

|---|---|---|---|---|---|---|

| Medium | 91 | 9 | 14.61 | 89.3 | 340 | 0.52 |

| 88 | 12 | 14.31 | 88.3 | 340 | 0.58 | |

| 85 | 15 | 13.95 | 89.3 | 360 | 0.70 | |

| Coarse | 80 | 20 | 13.40 | 85.3 | 270 | 0.80 |

| 80 | 20 | 13.58 | 84.0 | 280 | 0.85 | |

| Fine | 90 | 10 | 14.35 | 91.8 | 380 | 0.30 |

| 88.5 | 11.5 | 14.15 | 92.2 | 380 | 0.35 | |

| 87 | 13 | 14.15 | 90.0 | 350 | 0.38 | |

| Non-magnetic | 86 | 14%Ni. | 14.15 | 86.5 | 260 | 0.39 |

| Ultrafine | 97.2 | - | 15.12 | 94.5 | 240 | 0.18 |

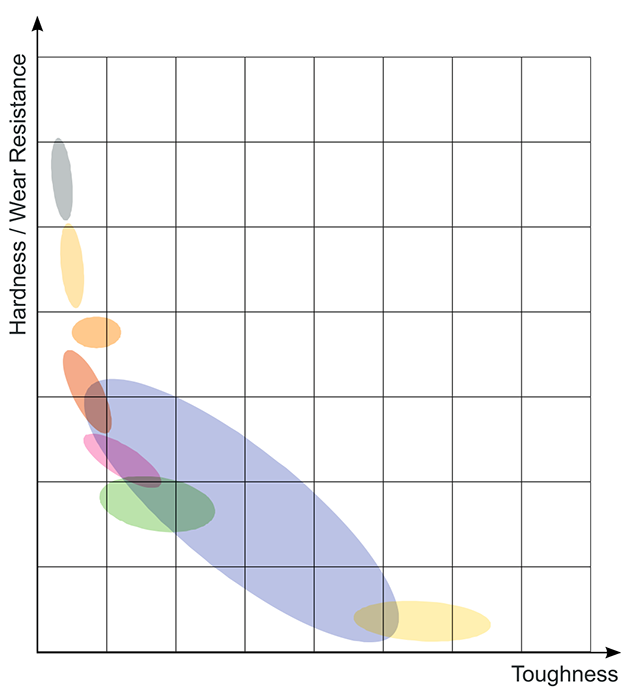

- Natural Diamond

- Poly-crystal Diamond / Diamond Coating

- Cubic Boron Nitride

- Ceramic(O)

- Ceramic(N)

- Cermet

- High Speed Steel

- Carbide

Criteria relevant for application

- Wear resistance, Hardness

- Compressive strength

- Impact strength

- Transverse rupture strength

- Tribological properties

- Specific weight

- Magnetic properties

- Modulus of elasticity, rigidity

- Thermal properties

- Corrosion resistance, resistance to oxidation

- Toughness

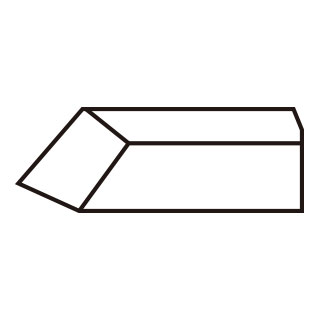

Forging Die

Cold and hot forging dies are used in high speed stamping application in auto parts industry. With a more accurate tungsten carbide selection, a higher tool life and a higher cost-effectiveness can be achieved.

Fastening Die

Our professional team has many years of experience in the fastening industry. We rely on in-depth knowledge of the characteristics of tungsten carbide and offer complete solution, focusing on high-end fastener mold production.

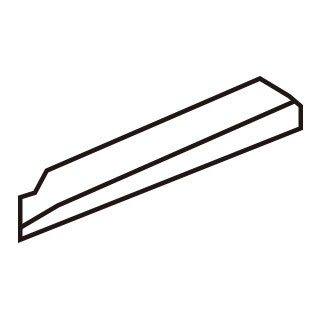

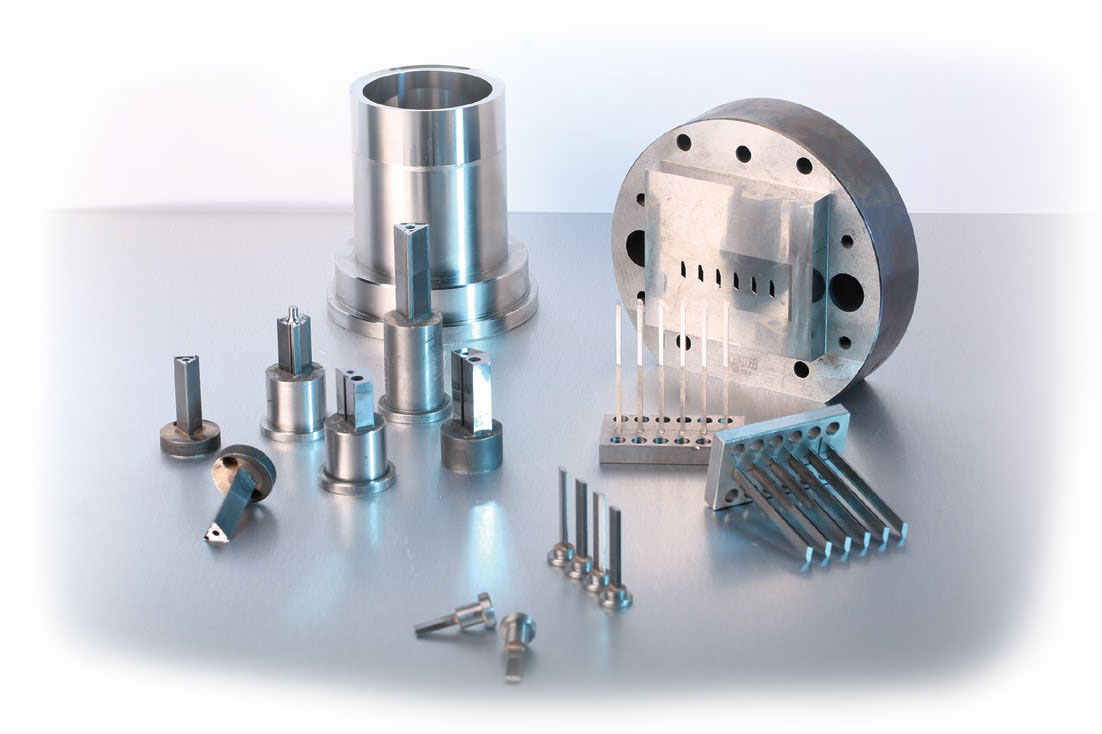

Spring Tool

Tools for high-end spring processing in all industries. Including feed roller, guide rail, mandril, dowel, cutter, pitch pin. We are confident about our high-end production and equipment inspections. We are able to meet all types of customer demands

Applies to various types of spring machine tools and dies (including tungsten carbide and steel)

Bearing Tool

Tools for bearing wheel ring processing, from high tenacity to heat resistance according to customer request.

Forging dies for various bearing, manufacture circular ball and taper ball, we focus on improving tooling life and provide cost-effective solution.

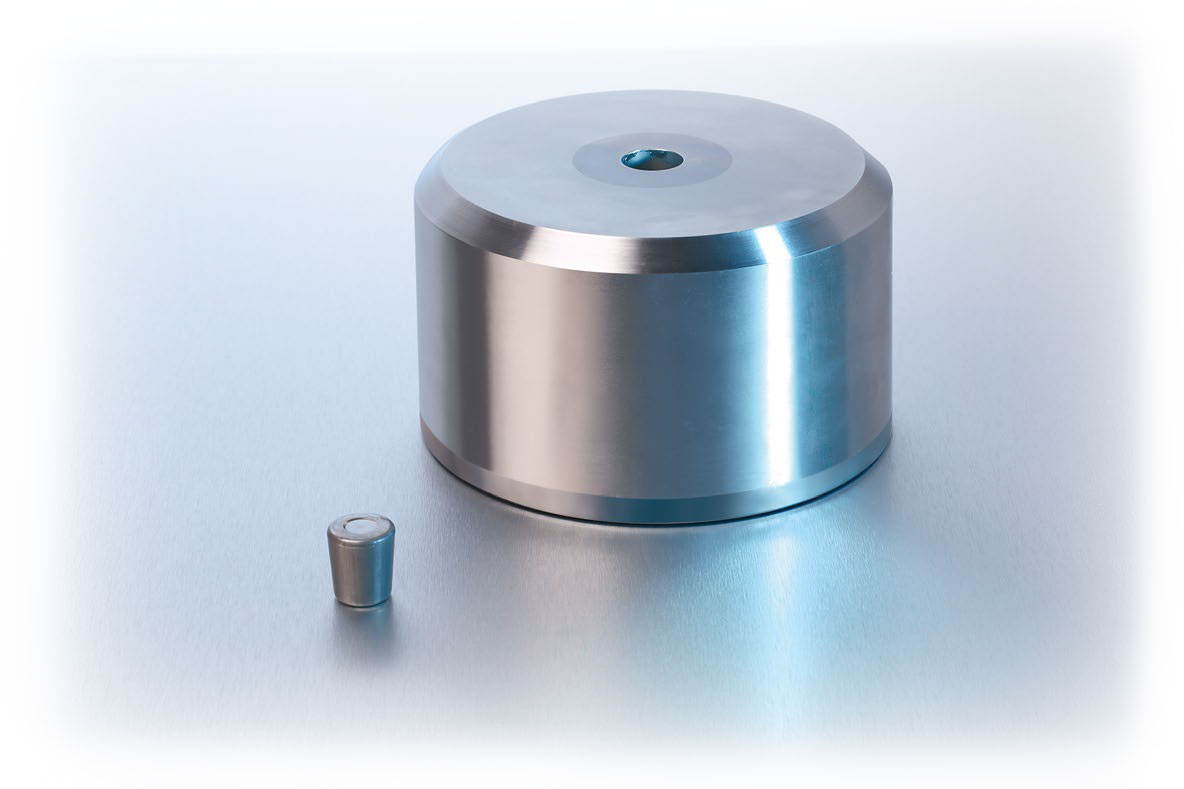

Powder Metallurgy Die

We are able to provide solutions used in manufacturing powder magnet molds with our non-magnetic grade series.

Widely used for manufacturing of various parts of alloy powder molding, in order to provide the customer with cost saving solutions. We are devoted to produce high precision, anti-abrasive molds and dies.

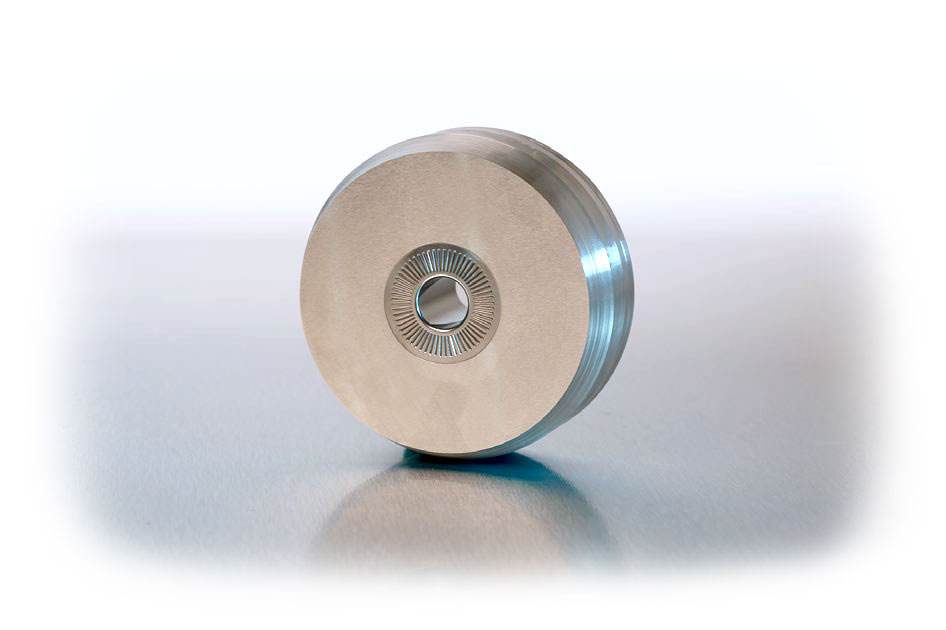

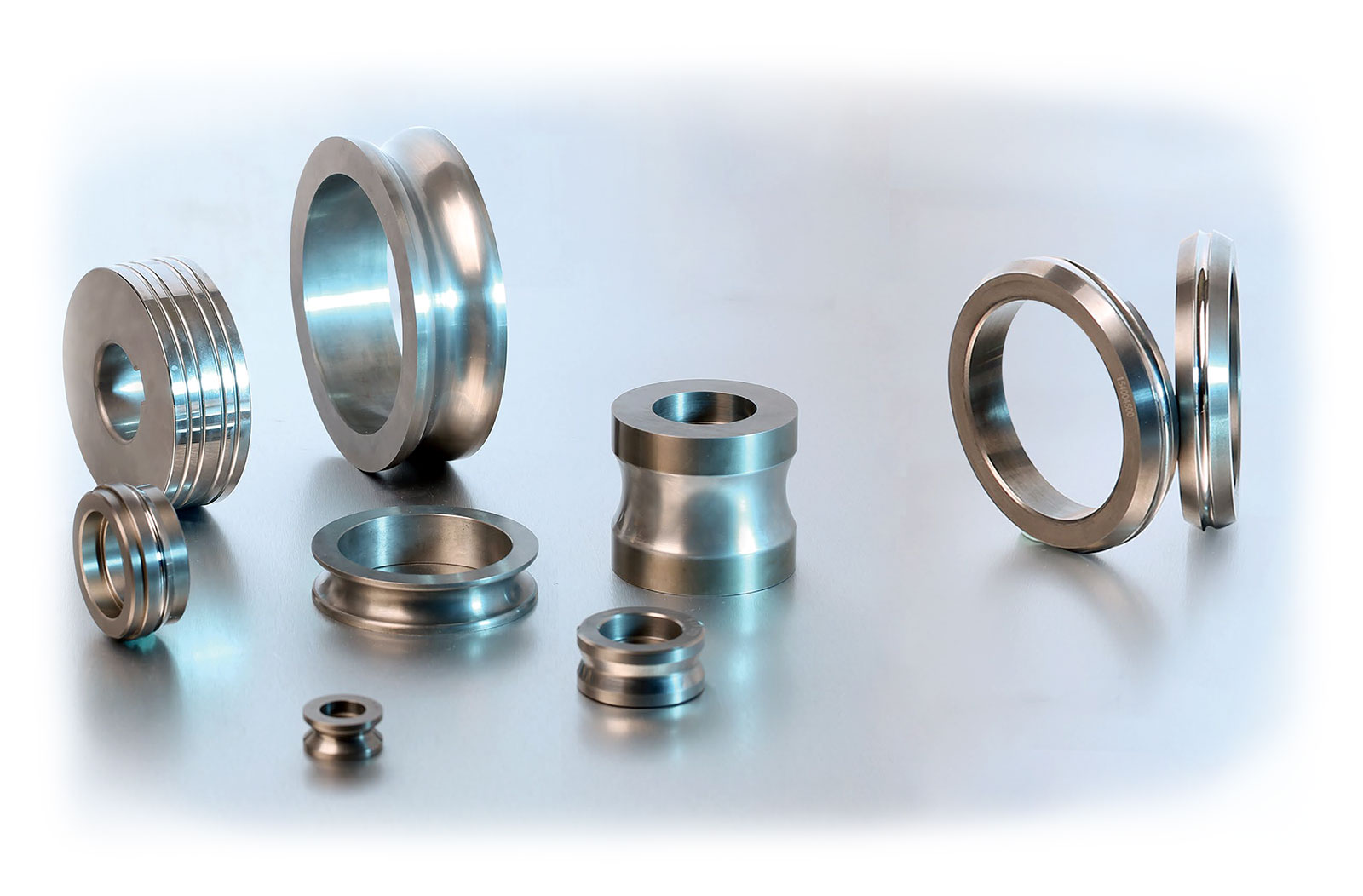

Deforming Wheel

The application is for cutting steel wire in Photovoltaic industry. Our advantage is in its large production capacity and customized processing which lets us assure that customer's high precision and anti-abrasive properties are met.

Optical mold

In order to meet customer request for harsh environment (high temperature and high pressure during pressing glass lens), we developed new OPT grade series, which can avoid oxidation and fog during customer processing; at the same time, we offer complete set of high precision, tool fitting clearance molds.

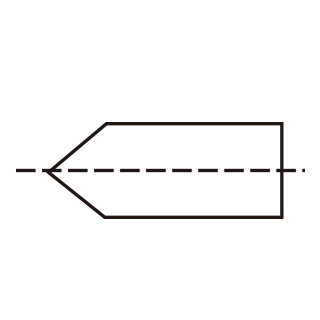

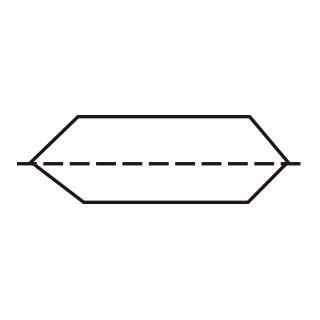

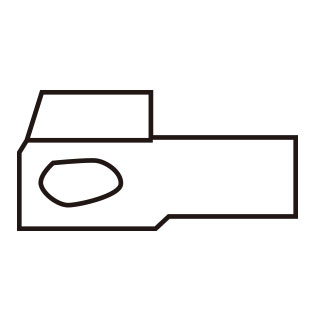

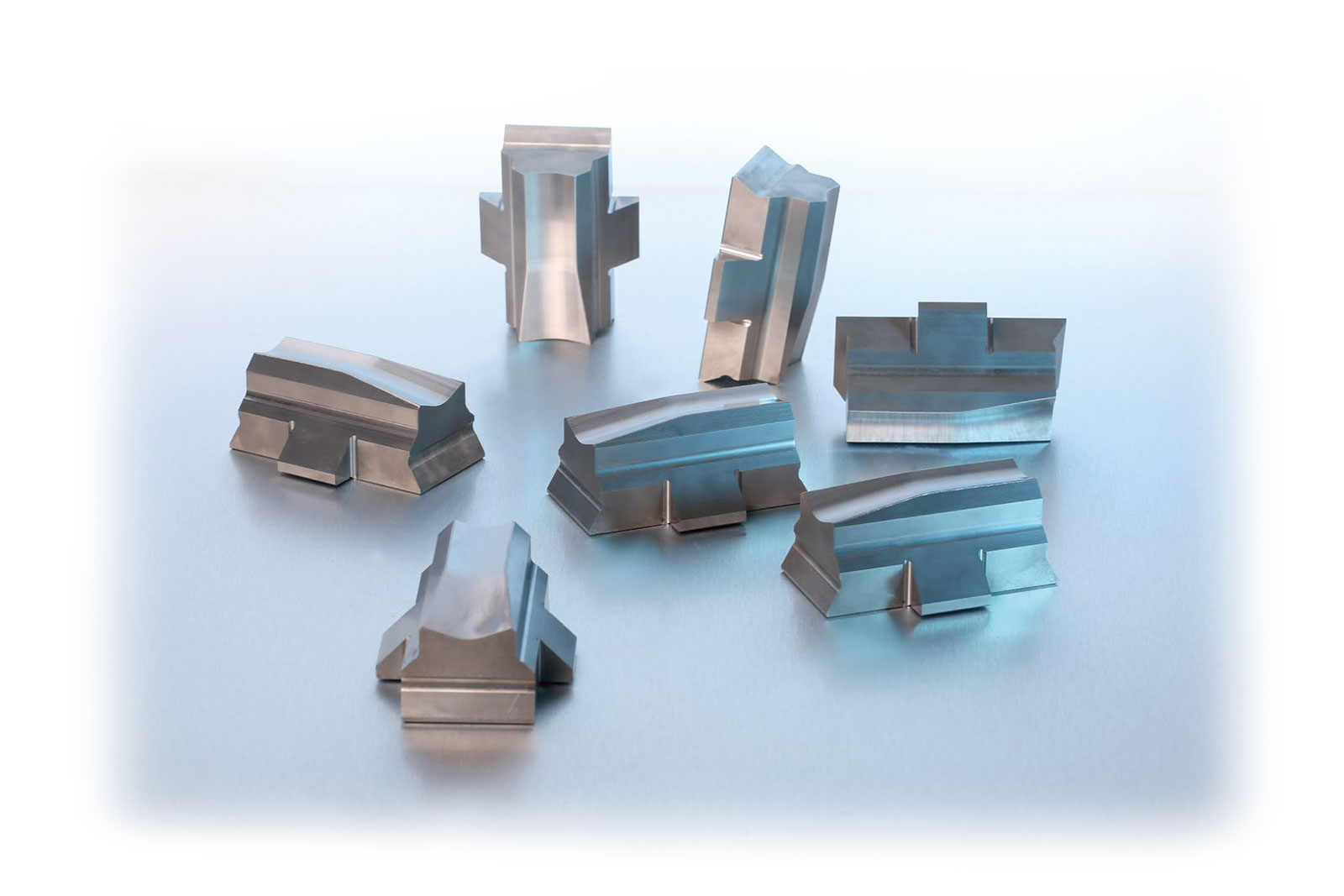

Rotary Swaging Hammer

Rotary swaging die for manufacturing of transmission shafts and steering shafts of car, we provide local services to shorten delivery time.

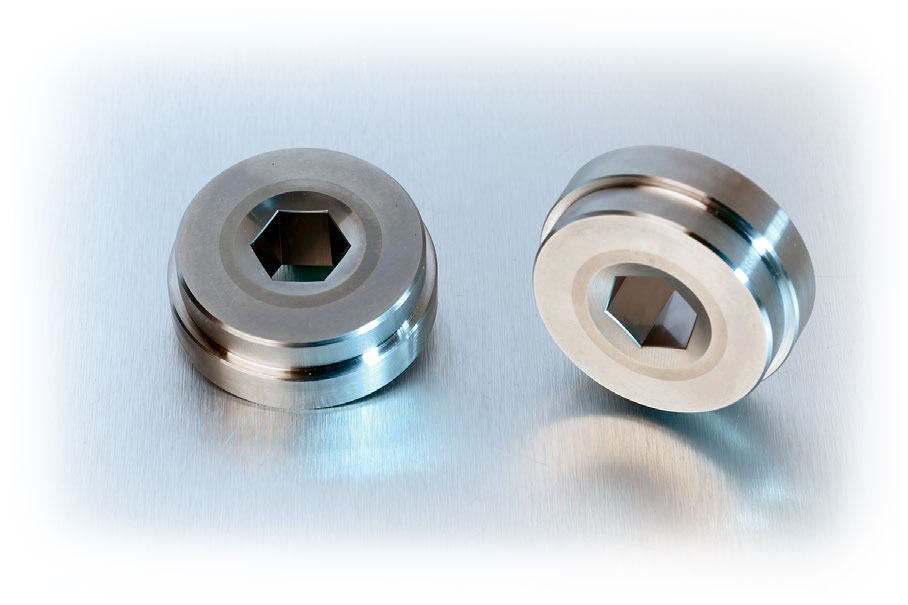

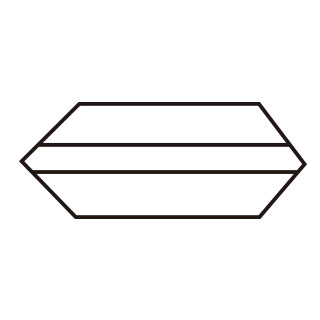

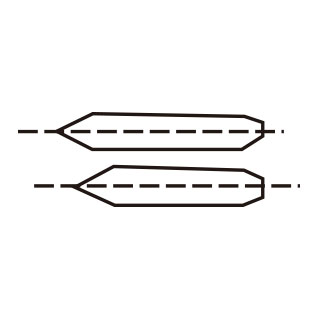

Drawing Die

Our drawing dies are widely used for processing steel wire and tubes, pulling process and shrinking process, as well as for processes with special shaped steel.

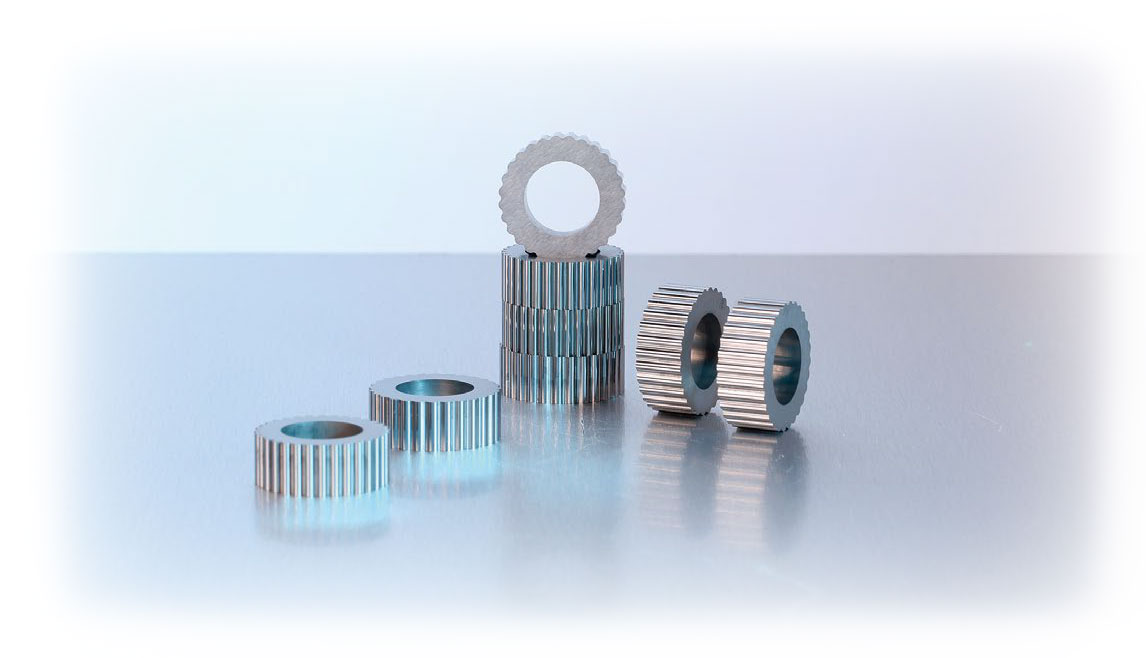

Roller

We offer cold rollers and wire feed rollers, with high tenacity, anti-abrasive characteristics, and with excellent surface quality, which can ensure high tooling life by reducing porosity and thermal cracks during operation.

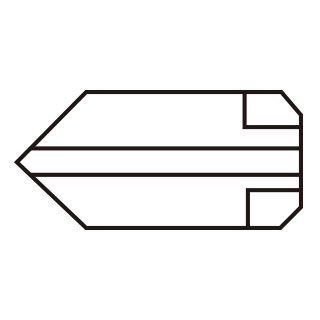

Can Tooling

By localizing production with high precision processing, we are able to provide custom solution for punch sleeve, cupper, and reduction die. Our non-magnetic grade effectively solves machine error problems. International experts within our group regularly visit us and help us improve manufacturing techniques and processes.