TOOLS FOR THREAD-ROLLING MACHINES

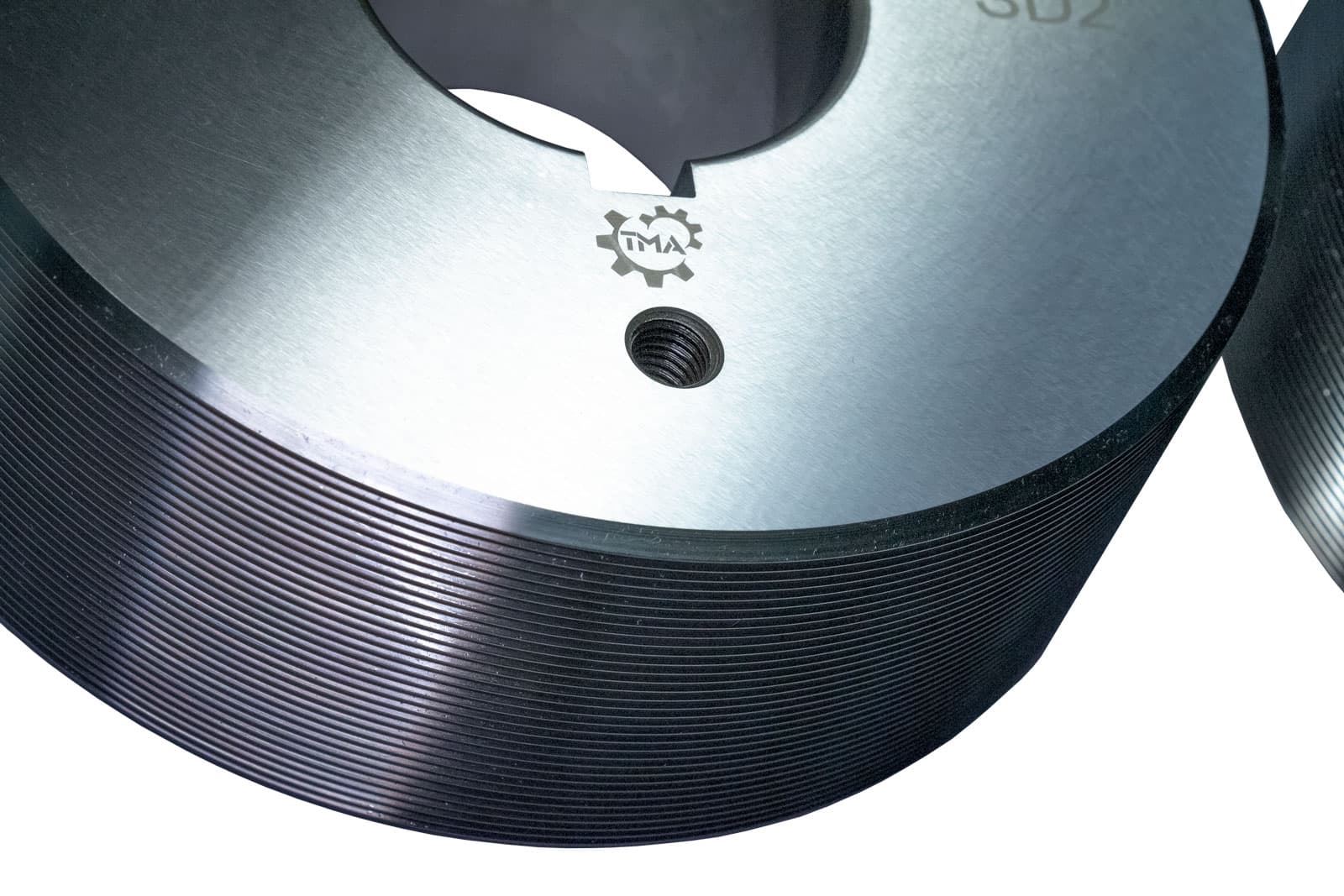

TMA CYLINDRICAL THREAD ROLLING DIES

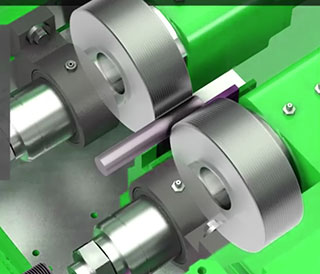

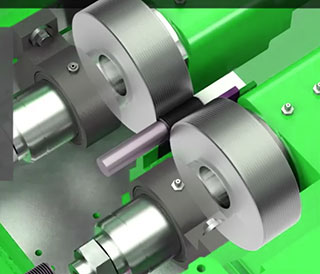

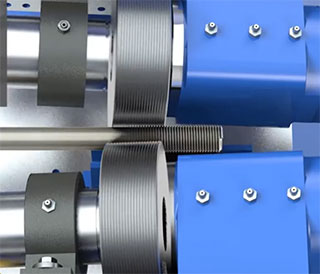

Thread rolling rollers with ring or screw thread are a type of thread rolling tool. With their help, they perform the operation of threading by cold plastic deformation on billets of various grades of ferrous, non-ferrous metals and their alloys on thread rolling, turning, revolving and even drilling machines. Thread rollers make a thread of Ø3 ÷ 68 mm in increments of 0.5 ÷ 6 mm of accuracy class 1, 2 and 3.

They are cylindrical disks, on the outer surface of which a single or multiple thread or ring turns are formed. The design dimensions of thread rolling rollers depend on the method of rolling, the type of thread being rolled and the design of the equipment used.

Depending on the method of rolling, they distinguish: rollers for threading with a radial feed, cylindrical rollers for rolling with a tangential feed, rollers for threading with an axial feed.

Depending on the design features of the equipment used, 2, 3 or even 4 rolling rollers are used in the work. The thread is high-quality, durable, with a low degree of roughness. Thread rolling dies are used for manufacturing in mass or large-scale production in the manufacture of studs, fasteners, shafts and other parts used in industry, agriculture and construction.

Type of thread being rolled - UNC, UNF, BSW, metric thread, ACME, ball screw thread, pipe thread.

Advantages of thread rolling with thread rolling rollers

Rolling threads is the most versatile and accurate rolling method, characterized by the widest technological capabilities in the manufacture of threads of various diameters, lengths and precision.

The wear resistance of thread rolling dies from Taiwan is 4-5 times higher than regular thread rolling dies. This is achieved by the brand of material used and an innovative approach in the field of production.

The use of thread rolling dies to obtain external threads has a number of important advantages.

- The ability to roll threads of any type, such as the american unified thin thread, the british inch thread, metric, trapezoidal, ball thread and even threading for pipes.

- Reduced cost of basic machine time compared to threading processes with chip formation.

- Save costly materials and eliminate chip disposal problems.

- High wear resistance and durability due to the strengthening of the surface layer of the profile.

- High resistance to fatigue fracture of the part due to the integrity of the direction of the material fibers.

- High resistance of threaded connections made with threaded rollers. This is about 50% higher than standard.

- Hardening of parts and products. Strength is enhanced by surface treatment using cold plastic deformation technologies.

- Wear resistance. Thread rolling rollers withstand pressure up to 1500 MPa.

- Simplicity of operation. To use the device you only need to fix it in the cartridges of machine tools.

- Universality. Thread rolling rollers can be used to cut or restore threads longer than 2 m.

- High quality profiles. After processing, the parts acquire mirror surfaces.

- High performance. Worpieces processing is very fast. This makes thread rolling rollers suitable for use in mass production.

The wear resistance of TMA Thread Rolling Dies is 4-5 times higher than regular thread rolling dies. This is achieved by the brand of material used and an innovative approach in the field of production.

Standard Thread Rolling Dies

Application:

- Single-Thread.

- V-Type Teeth, Pitch 0.5 - 5.0mm

- V-Type Teeth, 40TP1 - 5TP1

- Knurling Thread, and 40TP1 - 18TP1

- Parallel Thread.

Samples of products:

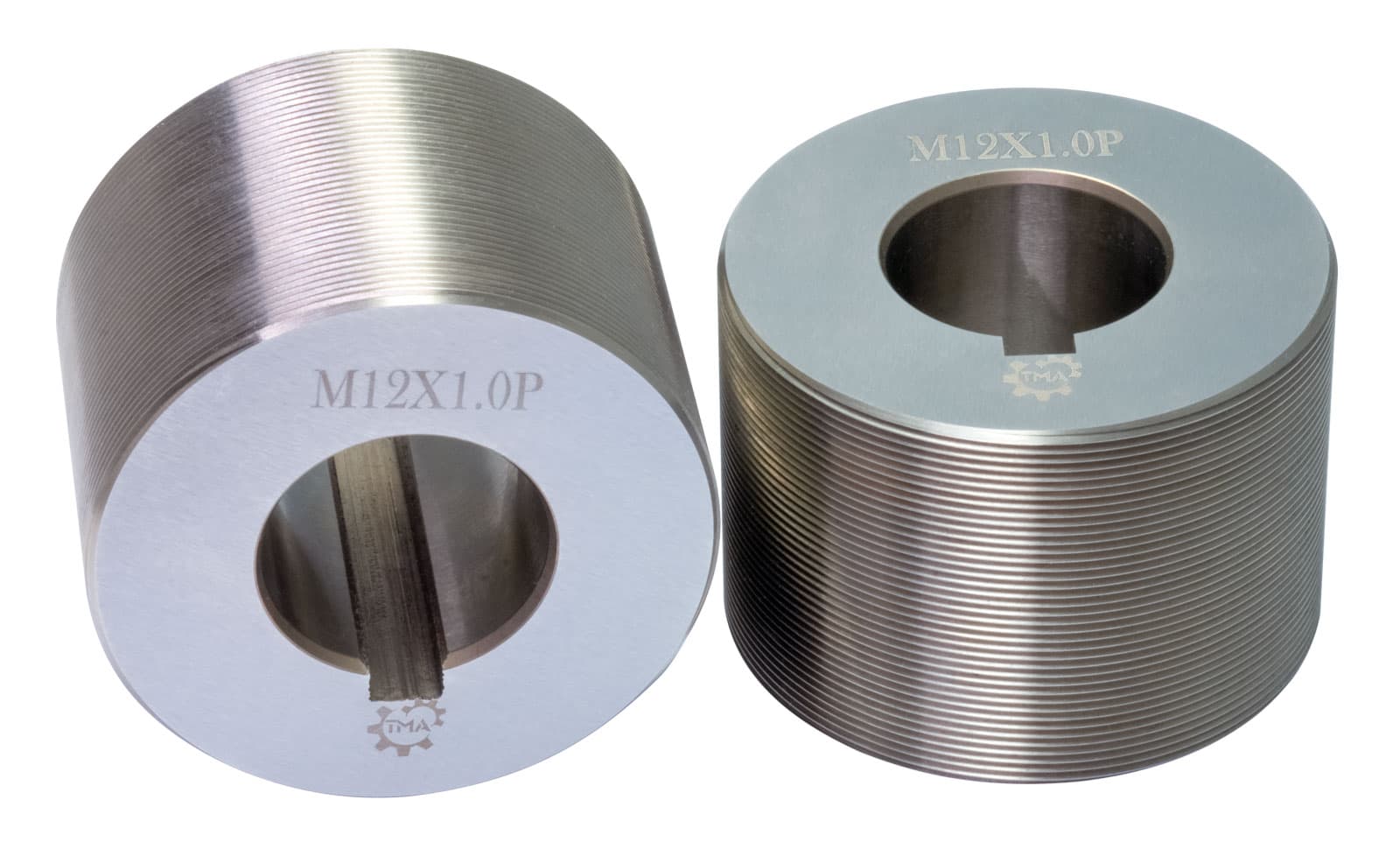

Special Thread Rolling Dies

Application:

- Over than Single-Thread.

- V-Type Teeth, Pitch out of 0.5mm - 5.0mm

- V-Type Teeth, out of 40TP1-5TP1

- Knurling Thread and metric size pitch

- Spline

- Worm Thread, ACME Thread, Buttress, Cycle Thread, Bottle Closure Thread etc.

- Taper thread.

- РFor rolling special material, Ex. SUS, Alloy Steel and hardness over than RC20.

Samples of products:

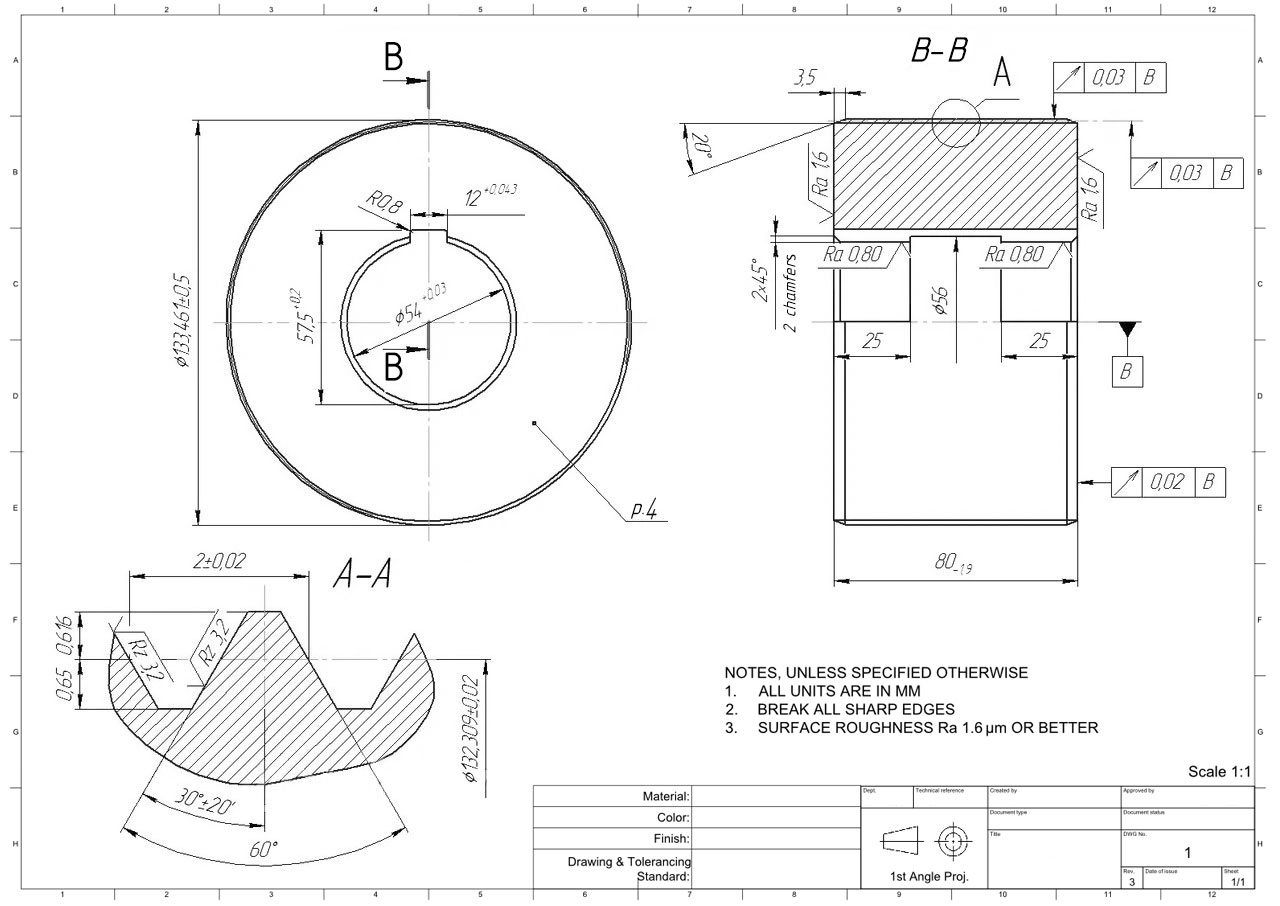

How to inquire Cylindrical Thread Rolling Dies

We are able to develop tools and accessories according to the drawings of finished products and technical requirements. To order thread rolling dies please offer below data:

- machine model or rolling die dimension (inside diameter of roller dies, maximal outside diameter of roller dies, length of the roller dies, keyway);

- shape of workpiece (thread length, thread profile, pitch or thread per inch, thread major diameter, pitch diameter);

- material of your products or material of roller dies;

- please specify thrufeed or infeed rolling;

- the direction of helical surface movement (right/left);

- workpiece drawing;

- potential addition requirements.

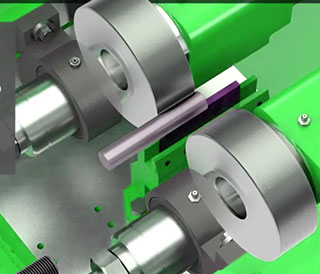

THREAD ROLLING TECHNOLOGY WITH CYLINDRICAL THREAD ROLLING DIES

Thread rolling dies are designed for rolling threads and shaped profiles on parts with a diameter of 3 mm to 68 mm and a pitch of 0.5 mm to 6 mm.

Thread rollers are a specialized technical tool designed to produce threads through plastic deformation. They are made in the form of cylindrical disks, on the outer surface of which there are ring turns or single-thread or multi-thread. The sizes of the rollers are selected depending on the preferred rolling method, type of thread and design of the equipment used.

Currently, the most popular are cylindrical devices designed for threading with a radical feed, which is carried out using a movable roller. They all have the same diameter and perform rotational movements, swaying in different directions. When rolling the thread, this tool carries away the workpiece, as a result of which the process of preparation and running is carried out.

Ultimately, the threads are pressed into the workpiece material, and, like a negative imprint, are threaded. At the end of the processing of the threaded surfaces of the rollers, the parts and the machined surface are in contact. In order for mutual contact of existing screw surfaces to occur, it is necessary that the thread elevation angle in thread rolling rollers corresponds to the elevation angle in the workpiece and the rollers are produced when rolling the right thread with the left thread, and, conversely, when rolling the left thread with the right one.

Taking into account that the larger diameters the thread rollers have, the higher the rolling process occurs, for example, the strength indicators and tool stiffness increase, the rule of equality of the angles of the rollers and the part must be perfectly observed.

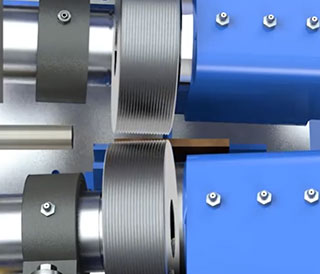

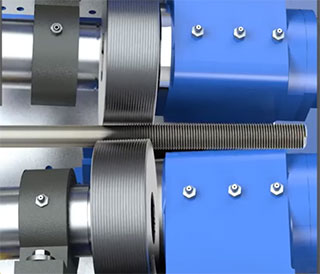

Infeed Rolling (Plunge)

Infeed rolling uses a timed cycle for increased production. It's used for general rolling of parts up to the maximum length of the dies, and also shouldered or headed work pieces like bolts.

- Work piece and dies are kept parallel on the machine.

- Work piece rotates between the dies. but has little to no axial movement.

- The axis of the two thread rollers are at angles of zero degrees; without machined angle.

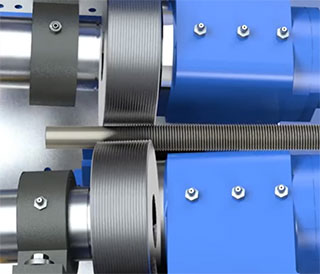

Thrufeed Rolling

Thrufeed rolling is used for rolling threads that exceed the maximum length of the dies, as well as for continuous rolling of long threaded bars.

- Tilting of the spindles causes the parts or bars to be axially fed through the dies.

- Work piece rides between the dies on a support blade.

- The axis of the two thread rollers are at the lead angle; machined angle = lead angle.

Retreat - Feed Rolling

Applicable to thread length of the working pieces longer than the rolling machine, and the entire piece is not rolled.

- The two rollers comprise a fixed roller at the left and a movable roller at the right. The working piece is placed in between the two rollers and the movable roller presses and grabs the working piece for rolling. After the required length has been achieved, the movable roller ejects it and the piece is completed.

- The axis of the two thread rollers are at the lead angle; machined angle = lead angle.

Thrust - Rolling

Applicable to higher precision screws and tight fittings.

- The working piece is placed in between the two thread rollers, where the working piece is rolled and completed.

- The axis of the two thread rollers are at an angle; machined angle < lead angle.